That's my current four foot duct pipe - it's just a "crimped" galvanized duct pipe. I'm concerned it has too much creosote and could explode if I get the exhaust too hot (above 450 Fahrenheit)....

So you can see there it is a 30 degree angle going off the wood stove.

So that slows down the exhaust and therefore builds up the pressure.

So NOW I have a laser-welded duct pipe that is stainless steel - so it can handle any high temperature with no concern of internal explosion as a fire.

That's what I currently have holding in the crimped galvanized stove pipe....

That's the Hermit Hut buried in the snow from a couple years ago....

I installed this pipe on an outside wood burner to replace a steel pipe that lasted 3 years. I thought stainless steel was the way to go, but not long into it's first season the pipe popped apart at the seam, warped so much, there is no getting it back together.

My guess is they had that OUTSIDE wood burner cranking at really high temp.

I'll double check the seam but....

Actually even of heavier gauge than I was expecting.

So that means it should absorb more heat to radiate it out more...

So I studied the stove pipe again and apparently it is only laser spot welded at one end of the pipe! The rest is a folded crimp - it's a better crimp than the galvanized pipe. Still I should probably drill a couple holes through that folded crimp and then put in a couple more metal duct screws. JUST to be safe. No need to take the risk of the pipe not holding.

Oder 6 inch Durablack stainless steel telescoping stove pipe.When I was putting the pipe together the pipe broke a its seams.Could not reseam pipe. Had order two pipes the second pipe had weld seams were the first one didn't.Tried to call but wait time was 26min.on hold.the pipe is very poor design.The seams are not put together like they should be.

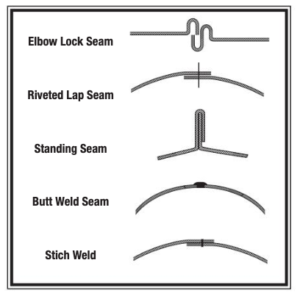

Spot-welded lock seams

So that means ONE spot weld and the rest of it is a "lock seam" - a fancy crimp...

So there you go...

One problem is that 6" diameter stainless steel pipe is slightly larger diameter than 6" black stove pipe.

Seems to have a lot of Ferrite in it making it extremely Magnetic. Most Stainless Steel is non--Magnetic

So here's the ACTUAL continuous laser welded seam but it's NOT stainless steel

hmmm - so it would rust but hold together better?

OK I can just use theGalvanized Full Clamp

holds 40 lbs of force.

So I'll get a bunch of those - only $4 each.

Wow - so the bottom of a wood boiler gasification furnace has a "horseshoe" ceramic refractory that takes the brunt of the 2000 degree heat BEFORE it then exits to go around the stainless steel. Fascinating.

The Insulating Fire Brick (IFB) is a type of soft brick made of

refractory ceramic material, a blend of alumina and silica, that can

withstand extremely high temperature applications and has a low thermal

conductivity. This IFB is an excellent insulator and reflects heat

well. Insulating Refractory Fire Bricks are light in weight and can be

easily cut by handheld hack saw or any other hand tool like chisel or

drill. They are ideal for creating custom shapes and cavities.

https://www.lynnmfg.com/insulating-fire-brick/

Maybe it's made from that stuff.

I was able to easily cut one of these bricks in half lengthwise to use as the base of the forge where the material sits. No crumbling or cracking at all and I used a hand saw for tree limbs...

https://www.amazon.com/Lynn-Universal-Baffle-Board-Superwool/dp/B0716M86PQ?ref_=ast_sto_dp&th=1

No comments:

Post a Comment