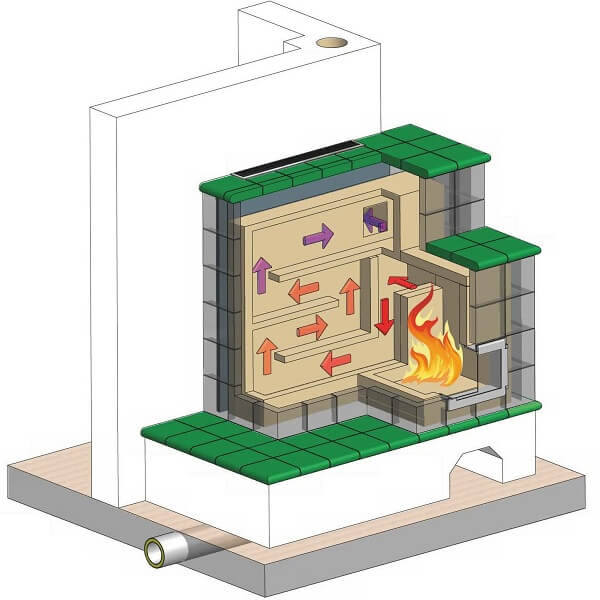

Donkey decided to go with a batch box design, and NO barrel. This is the first time I have seen a rocket mass heater without a barrel or something that looks barrel-like. The fire is low, goes up a heat riser and is left in an open area referred to as "the stratification chamber" (sometimes called "the bell"). The exhaust is taken out low.THIS is what I'm talking about!!! Nothing fancy - and yet a 90% efficiency burn!!

Amazing design. None of this "barrel" rise and "j-tube" stuff.... No "benches" - just radiating heat.

So the only fancy part is the secondary air feeder tube - which is metal. I need to figure out how that is configured. Otherwise I have everything - bricks and the cob is sand and clay.... (no mortar)....

But, you are right, the lack of a barrel means that the total short term heat is not much. So expect to burn for a while to get the heat up. BUT! Then you have many hours of heat coming off the bricks, long after the fire is out.hmm - I had not thought of that. Very interesting....

I think if I just surround a metal stove with all my bricks - it would not be as CLEAN of a burn but.... it would radiate the heat.

But masonry heaters do not burn as clean or as efficiently as rocket mass heaters.... little differences, but the big one, in this case, is the insulated riser. A conventional wood stove attempts to extract the heat immediately. A masonry stove attempts to store the heat immediately. A rocket mass heater attempts to compound the heat immediately - to get a more complete burn. Then the rocket mass heater will focus on extracting the heat into the room (like a conventional wood stove) or storing it (like a masonry stove).

The space is necessary for the heat of the exhaust to be absorbed by the surrounding masonry, which then radiates that heat.https://www.youtube.com/watch?v=U7kqu1XvsXY

https://insteading.com/blog/masonry-heater/

Swedish Kakelugn were traditionally made using only three materials; clay, sand and water. Their interior walls consisted of factory produced glazed tiles while the firebox and inner flues were made from clay bricks layed in clay mortar.https://www.pyromasse.ca/en/origin.html

The clay bricks of the original Kakelung were not very durable and so about every 15 to 20 years the whole Kakelung would be dismantled and then rebuilt using the original set of tiles. The clay mortar, used for its elasticity, unlike cement based mortar never set hard and so dismantling and rebuilding a Kakelung was a relatively straight-forward operation.

https://www.firespeaking.com/wp-content/uploads/2011/09/Cabin-Stove-Construction-Drawings.pdf

seems like a Masonry heater is still much EASIER to build than a rocket stove masonry heater....

on the Casserole top lid Door vid

That's the inside design for this rocket mass heater

No comments:

Post a Comment