The VVT is known to rust into a fixed position in the presence of accumulated condensate (eg: water) in the crankcase because of an inoperative PCV system. The Crank Position Sensor is know to die from leakages --- more an indicator of it's failure --- of oil from the crankcase. If it leaks, it's assumed as bad.

it would occasionally set that overadvanced cam code. I just cleared it when it set, never replaced any parts for that After several oil changes using full sythetic oil that code stopped setting. That system depends on good clean oil and does not do well if oil changes are neglected. the exhaust camshaft is over-advanced. It runs rough at all times, when starting, idling, and all through acceleration.

From what I've read online, and combined with my experience with other vehicles, I figure it could be one of several possible issues:

Bad camshaft position sensor

Bad VVT Solenoid

Bad Camshaft Phaser

Timing chain has jumped time/wearing outMY 2002 GMC ENVOY SLT 4.2L NOW HAS 640,000 MILES ON THE ORIGINAL ENGINE in 2020Then he blew white smoke out exhaust with smell of fuel - so head gasket leaking? coolant into fuel....no response from 2022 Fall.The VVT actually is at full advance at idle, no valve overlap. At around 1500 RPM it goes to around 12 degrees, which is normal run mode. At 3000-3500 RPM the VVT goes into full retard, which is around 25 degrees. When driving a Trailblazer/Envoy you can definitely feel the difference when it goes into full retard. It's almost like the secondaries on a 4 barrel opening up.possible exhaust manifold leak. A good, experienced ear can identify this and, if it's like others I've read about, it will be coming from the forward end of the manifold. A TSB (#02-06-01-032) identified this problem and calls for new gasket and new bolts. Seems the original bolts would not stay tight (either too long or too ductile, depending on who you believe) and a slight leak would develop.

Rebuilt transmission and no more ticking.

cam and crank sensors being out of sync. I then took it to the local GM dealership to confirm the diagnosis and to find out which part needed replacing (ie., cam sensor, crank sensor, cam solenoid or some combination of things). They told me that the oil was low and that was the cause of the engine knock and that the engine needs to be replaced!?! I had just recently changed the oil myself - and it wasn't burning any.I have this same knocking noise in my 04 Trailblazer. I took it in and the service manager told me it was normal at startup until the engine warmed up. So I guess GM hasn't tried to fix this problem dating back to '01. Seems typical of GM.

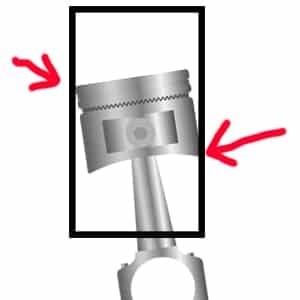

Piston to bore clearance (piston slap)The steel sleeves are thin in the stock alum block.

Cast pistons are .020 over at the smallest over size.GM engines are generally notorious for piston slap. This is because things have to heat up and expand for the piston slap to go away. Another thing to note is the 4.2 I6 is DOHC design. There are a lot of moving parts on that babys valvetrain. When cold, it can be noisy. The most GM will do is check your engine to see if you have a defective liner, they will not replace an engine unless there is damage, trust me, there a few people that actually had a liner go bad and they went through heck and back getting the engine to be replaced.failed crankshaft thust bearings on the 4.2L. Once you get some slop in the thrust bearing, too much of a load gets put on the main and connecting rod bearings, causing them to go out. If the engine doesn't show drastic signs of oil starvation, I'd say the thrust bearing was the root cause.some oil down in the spark plug wells is super common on this kind of engine design. I've seen it in many different make/model OHC engines with the plugs recessed way down in the cylinder head(s). Each plug tower has a seal that seals the valve cover off from the cylinder head. Most are just an O-ring, but the vortec 4.2L has kind of egg shaped wells. RTV is probably used on our 4.2's.there was engine oil on the threads of some of the plugs. I don't think it's good and it leads me to believe I have a cylinder sleeve that is busted (or something to that extent). Has anyone checked into this?

Although not as strong as forged pistons, hypereutectic pistons offer increased strength that raises piston reliability at a lower cost. Hypereutectic pistons also don't experience as much thermal expansion as forged units, which means they can be mated to their respective cylinder bores with tighter tolerances. hypereutectoid. / (ˌhaɪpəjuːˈtɛktɪk) / adjective. (of a mixture or alloy with two components) containing more of the minor component

Piston Slap video - what it sounds like

Okay, for those of you that have the "diesel" sound in the morning and after it your TV warms up it's gone, that is "piston slap". The pistons in almost all NA GM vehicles are of a hypereutectic construction. They are made for long life, limited scuffing and light duty (read NOT performance). They are a relatively light piston. Because of their construction and metal properties, they do "shrink" when cold and they do "expand" when warm. They shortness of the piston skirts (especially the non coated skirts) tend to exacerbate the "rocking" of the piston (piston slap) when cold. This is for the most part normal. If you let your vehicle warm up properly and do NOT race the vehicle or load it greatly when cold, your engine can and more likely than not last for well over 150,xxx miles

Has nothing to do with the oil hitting the valves to cushion them - in that case you'd have a lot of oil burning and smoke! It's the cold engine block and pistons that expand as it warms up, and the noise fades away.It once oil hits the valves and starts cushioning them (this should take about 30 seconds to 1 minute) any initial rattle should stop.I noticed that now the RPM's are higher at start up. Its like instead of fixing the problem, they made the truck warm up faster so I won't notice the noise.The original design fan clutch can make a cycling click or tick noise repeating once or twice a second when it's cold for a few minutes until things warm up. The clicking is the solenoid in the clutch being actuated by the PCM that controls how much the clutch is engaged. The new design clutch that came out in June-July 2005 with the higher minimum speed for poor AC cooling issues supposedly doesn't make this noise.Some customers may comment on an underhood tick noise heard while the vehicle is idling. Technicians may find that the noise does not increase or decrease with changes in the engine idle RPM. The tick noise occurs at approximately one second intervals.

Cause

This condition may be caused by the electro-viscous fan clutch control function of the Powertrain Control Module (PCM) attempting to keep the fan speed between 300-600 revolutions per minute (RPM). At idle, the cooling fan speed will drag to approximately 500 RPM then oscillate between 300 and 600 RPM. When the fan speed drops below 500 RPM, the PCM will pulse the fan control solenoid. The pulsing of the

Bulletin No.: 05-06-02-004

Date: April 06, 2005

solenoid is the cause of the ticking noise.

They did a PCM reprogram as per bulletin 05-06-02-004. When they started it up again, no noise. I got into it at about 8:30 and it was cold again and I heard no sounds.i have variable valve timing(VVT-LIVC) SO i can take advantage of the 91 octane This can be see as retarded ignition timing ( I get upwards of 42 degrees advanced timing with REAL 91 octane) shortly after pumping 6-9 gallons of fuel form these Shell and Acro stations the ignition timing dropped to lower levels... which means my performance and MPG are going to suffer but I got less MPG after using it my MPG highway dropped from 25 to 19.5 using Acro gas4 gal of Shell V-Power and top off the rest of the tank with 87 to get a little more potent maintenance dose of Shell's deposit control additive.'Light chatter sound"... I wonder if you are hearing the fuel injectors. They make a light ticking sound when they operate. The a/c compressor and the alternator are on the driver's side too.failing cylinder liner.Although 2003 & later motors have polymer coated pistons to help reduce piston slap, I'm thinking it wasn't a 100% cure as they've now added squirters to the rods to put add'l oil on the cylinder walls for 2006.a hydraulic tappet and they usually don't make the same heavy tapping sound a bad lifter makes. (Sounds like you may have some piston slap, which can resemble that sound).Next time you start cold and she's tapping, raise the hood and see if you can tell if the noise is at the very top of the engine around where the valve cover meets the head or a little below. If it is, the noise might be valve train related. If the noise is coming from farther down the engine, like below the seam of where the head and block meet, its piston slap.The dealer diagnosed it as piston slap and GM extended the warranty on the engine to 100K miles. Once I received the warranty extension I switched to Mobil 1 fully synthetic. The switch has nearly eliminated the "tick". The reason is synthetics flow better then conventional oil when cold. Now when the temps are mild, the noise might last 2-3 seconds on a cold startyou're most likely hearing piston slap. The 4.2L uses short skirt pistons, which while reducing mass and aiding in efficiency, can cause piston slap.....if your engine sounds a bit like a diesel for the first few moments after starting, that's what you're hearing.Late in the '02 model year, GM changed over to polymer coated pistons to help reduce and/or eliminate the piston slap present in these engines.you are at the least slowing down the response time of the exhaust cam phase actuator mechanism, since it's function relies on proper oil viscosity as per the service manual. Quote from GM SI:"Engine oil has a major impact upon the camshaft actuation system's responsiveness. Oil temperature, viscosity, and quality can slow and/or inhibit the phaser's ability to reach a desired phase angle."The slightly heavier viscosity when cold seems to cushion the piston noise against the bore of the cylinder better, reducing the "diesel" type noise I was hearing. It's still there but reduced. Goes away completely when everying heats up and expands. GM supposedly addressed the problem I described with a polymer graphite coating on the piston skirtsGerman Castrol synthetic 100% PAO oil. MOA is filled with all the oil stabilizers, anti-foaming agents and anti-wear ingredients that typically go into a high dollar oil base stock.cracking of an engine cylinder bore liner,Somebody mentioned the valve lash adjusters but that is a different noise. More like an old fashion lifter tick in engines of old. When below zero they sometimes tick for a minute until the oil gets pumping. There is I believe a certain amount of engine noise that is normal? Does anybody agree with this? Mostly when cold in the winter mornings. Disappointing that GM had this cast piston slap problem. Poor design I think.the vacuum not allowing the cast aluminum piston to slap. They are very short pistons and in later years they have made pistons with longer skirts and put a polymer on the skirts so they don't knock. I guess this problem occurs in other GM engines as well. Even the Corvettes! Imagine your Corvette knocking like that on cold start up? That would be hard to take, bad enough on the SUV. Other noises I've had which are commonKnocking here is caused by failed crankshaft bearings and is mostly caused from loss of oil pressure or running the engine without enough oil.Other than removing spark plugs and checking for piston slap or connecting rod play i am partial to further investigating it by removing the 2 access plugs and maybe it will allow me some more evidence on the chain tensionthe loudest area is right ( red arrow ) at the front drivers side camshaft / valve cover bolt checking bolts along the path towards passenger side it lessensnumber 1 rod bearing had failed due to a one time low oil level. Ended up replacing the motor with a lower mileage engine from a recycler. A LOT of work for not paying attention to the oil level.Could also be an exhaust manifold leak that seals when it heats and expands.bad bearings so long the oil psi is ok which should really be the first thing to check then compression test. Connecting rod bearings may be checked by bringing each piston just past tdc. At this point you will used a long extension to push downward. If you hear a clunk then its a bearing.04 buick rainier 4.2 dealer said to replace valve cover assembly also said 90% of the noise is from pistons fix replace engine $$$Turns out, it's an exhaust valve that got too hot because of a crack in my manifoldThe vaccum is created because there's supposed to be a hose over that that sucks in clean air from the plenum box. The other hose brings out crank case fumes and oil residue that's why there's a suction. 2nd thing is, these trucks are old, more than likely the Lifter got a little play in them it's fine as long as they aren't collapsed your good, just make sure you change your oil regularly and correctly. Chances are you probably paid less than 4k for your trailblazer anyways and if you did it's gonna have issues. When I bought mine the ball joints were shot, valve cover gasket was leaking oil all over, vvt solenoid was clogged etc, but over time I've fixed all that shit. Save some money up to buy a new vehicle just in case but drive that SUV till it stops running, either that or get your lifters fixed, I mean honestly it might be cheaper just to put a new engine in, simply because shops hate working on the 4.2 engine, and either way you're probably staring at over 1k worth of work regardless, unless you do it yourself.:Using a stethoscope I heard the noise coming from the area of the VVT Phaser.No codes for the VVT solenoid at all.That clean air is supposed to be drawn into that nipple and air flows into the valve cover to wash the crankcase of fumes from cylinder blowby and the after-byproducts of internal combustion - including water also from the humidity in the air.If it does NOT purge the crankcase --- being drawn into the vacuum side of the PCV system --- it will keep collecting condensate (water) in the pan.Every time you shut the engine off, then that water partially falls out of suspension and gets to reconsolidate and create rust and corrosion to the parts inside the engine.OK --- so what does this diatribe by me info do for you?If you haven't rusted the mechanism of the VVT - there's something else to consider.When water collects in the lowest part of the crankcase (the pan) and gets drawn up by the oil pump where it gets mixed with the lube oil, it gets to eat your noble parts like aluminum and iron.One of the things that suffers the most from water contamination is the camshaft and followers which are in critical need of fully slippery oil for it to live.

The bearings, piston rings and chains can take a lot of water abuse but the CAM is under serious loads that require very clean, non-contaminated oil at all times.It is not impossible to grind the cam flat or weld a follower to the lobe for lack of decent oil - and that won't necessarily show up on a compression test; so a compression testy will usually only find things that are really wrong.A tossed follower [cam followers also known as hydraulic lifters] or flat cam lobe WILL make a difference in performance at higher than cranking or idling RPM because you have 2 intakes and 2 exhaust valves per cylinder and I've seen these Atlas engine toss a single follower from time to time.So - now I've given you another place to check out.PART 2 --- I had a partially collapsed piston from the joker who bored my block and pressed the piston pins and rods.

........... because he crushed one of the pistons - not enough to be measurable - but enough to make a slapping noise until the piston got warmed up and the noise went away.I detested that little red-headed twerp for lying to me like he did - even to this day - as he cost me a stroker 350-383 build that I got to do a second time on MY dime!You MAY have a broken piston. It gets quiet as it warms up --- that's a big hint.

:cam position sensor code awhile back and thought nothing of it, I replaced the sensorTiming chain guides and tensioner wears out! You get that knock at cold start and it goes almost away after warm up but if you listen close you hear the chain going tick tick tick. That is the slack in the chain. The tensioner was fully extended to the max. Guide had groves worn into them.I change the oil on schedule and use Mobil One. So it's just wear from lots of miles!As the engine warms up the oil tightens up the tensioner? I've never changed the timing chain. Today it made no noise whatsoever. But it's not cold outside today.a bad chain tensioner / stretched timing chain / worn guide /` s ?Putting a screwdriver to my ear at the valve cover bolt at the front where the noise seems to be strongestTo me it doesn`t sound like the valvetrain / rods / pistons making the noiseAfter watching this video someone uploaded i wonder if this is the issue causing the knocking with the chain slapping the upper guide at the valve cover location ?Somebody has mentioned Cold Carbon Knock? [injectors clogged and need Techron treatment to fix] I can see down the spark plug holes with a pin light and see tops of pistons are black. So I'm running Techron in my gas each tank. Will carbon on the tops of the pistons make the knock only when cold in the mornings? It seems to be worse now that the weather is colder this fall?my motor and transmission mounts are going bad and the noise seems to get worse the more they deteriorate.Dealers checked it. And said this motor is Notorious for this noise. Gave me a BG products oil conditioner. And it goes away between oil changes as long as I use that one can every time. It sounds as if it is a hydraulic lifter. But I have change 2 coil packs out on this motor and the sound is completely gone until one starts going out again then it's slightly comes back and gets worse until the pack is gone.I did the Seafoam through the brake booster vacuum line trick a few weeks ago and it made a big difference on noise. I had an annoying "tick" as well.BG MOA ("Motor Oil Additive") vastly improves the lubrication properties of the motor oil, therefore greatly reducing friction to internal components and extending engine life. Watch some BG bench test videos on YouTube. I've seen actual bench tests at a car dealership 25 years ago and since have purchased BG products. There is a noticeable difference with a quieter engine and smoother operation. Try the products. It's not an expensive investment for your already expensive investment

No comments:

Post a Comment