https://batchrocket.eu/en/designs

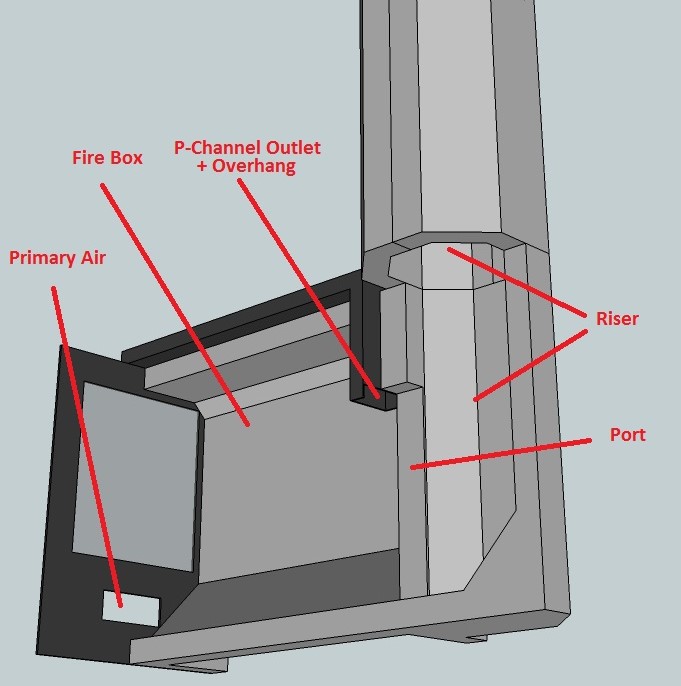

So that's the design to create the Double Vortex reburn or secondary burn in the riser.

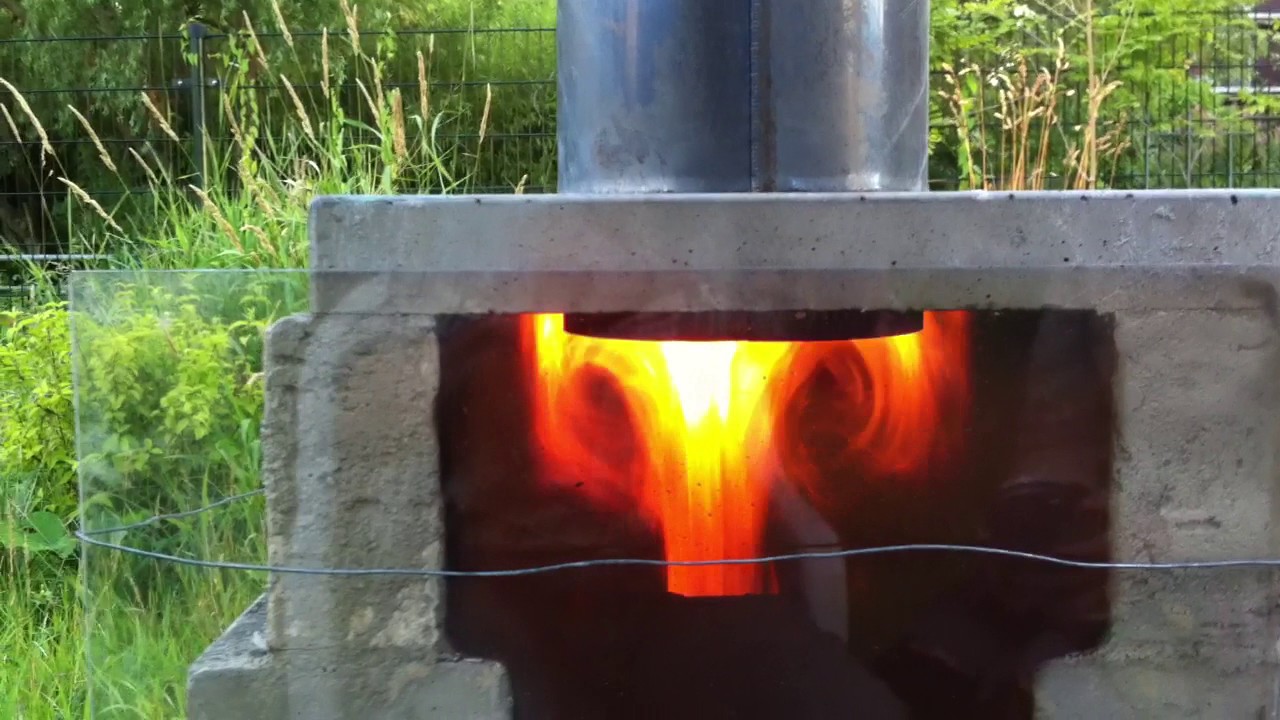

His experiment proved the double vortex could be formed in a number of directions, 45 degrees up being not the only one.

Of course I tried this at home beforehand and the results were encouraging.

https://donkey32.proboards.com/thread/2341/different-batch-core-riser-all

So that is a very similar design - the baffle is above and so the double vortex is created from the baffle - just as in my stove modification.

when your flames are turning blue it means you have reached about max flame temp you can do.

I wonder if I MAXXED out the temperature gun? Because it never went over 987 F. and the emissivity rating probably kept it that low as the maximum.

Anytime you see blue in a fire it is hotter than white. The range is between 2,600 and 3,000 degrees Fahrenheit and its the most oxygen-rich type of flame.

Well I saw LOTS of blue light - so no wonder I didn't smell any wood gas pollution in the smoke.

Back to my "Double Vortex" - ok it was intermittent - but there was definitely VORTEX action!!

Here's proof the flames can go up the back also - behind the baffle

yeah the emissivity of wood is .86 while the infrared gun was set at water emissivity of .96.

So that means I was losing one tenth of the temperature!!

So that means I definitely MAXED out the thermometer gun rating since it's only about 1000 and 1/10th of 980 is over 1000.

980 + 98= 1078.

So it's a good thing I didn't adjust the emissivity for wood since it would have broke the infrared sensor. haha.

Inhalation hazards - keep it wet, it won't go into the air. Particle size smaller than what you can see

Ceramic hazards....

No comments:

Post a Comment