So the first place I ordered this part from - they are not clear about whether they have the part in stock or not - and then they process the charge before telling you when the part will come in!! So I found an ebay seller that had the part in stock and it has already shipped. The first place said the part would not ship until February and so I got a refund and canceled the order. Now did they have to cancel their order from the manufacturer? I don't know but that seems a strange way of doing business! A third vendor asks people to email them first to ask if the part is in stock BEFORE ordering it - and I did that and I was told it was NOT in stock. haha.

Anyway so... I got the first two parts already - a stainless steel coupler and the stainless steel pipe - both 1/2 inch - and they fit together even though they were from two different companies - again I needed to make sure they were in stock - as the supply chain is way delayed these days. So then once the 90 degree elbow comes in - then I will have a "secondary air" S-valve. I will run it along the bottom of the stove to the front door. Then I will use a hack saw - I just got 12 inch hack saw blades to connect to my manual bow saw.

So I will put the vertical elbow against the back wall and have it held between the two pieces of ceramic fiber board to insulate and heat up the fire box. Then I will have ceramic fiber board along the bottom of the steel baffle. Then I will make angled ceramic fiber board - for the side walls to hold a second ceramic baffle that will angle towards the top.

It will look like this.

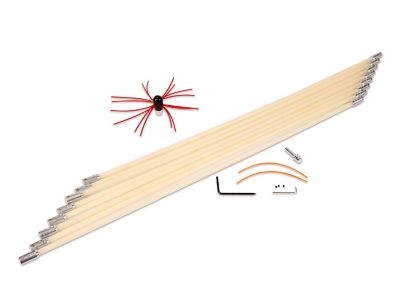

So now I ordered a Sooteater - but the key is to get the WHITE thinner nylon rods as they can bend 90 degrees for the 90 degree elbow....

So the white version is NOT in stock locally and the local DIY stores were marking up the price a ton. So I ordered it from a wholesale distributor based in Hong Kong that has a Los Angeles Warehouse. The price was over 50% less since it included 30 feet of nylon rod extensions versus just the 24 feet. These nylon rods get frayed from the 90 degree elbow vibration rotation. So you don't want the rod to break off....

there is an Allen bolt inside the ball that is used to tighten and loosen the whips. But it cannot be seen when the drill adapter is attached to the ball. So be sure they are very tight before cleaning chimney.Make sure you tighten the hex screw with the provided wrench on the black cleaning head. I didn’t tighten this the first time I used it and all of the brush strings came loose inside my stove pipe.

Be SURE to use a cordless drill only and set the clutch resistance LOW to start, then adjust to suit.You should use Rutland Creosote Remover or some similar product as directed. The creosote needs to be dried out in order to properly remove it..It is important to remember to read the instructions that say not to reverse the drill on the way out.This will cause the threaded rods to come unthread and leave the brush inside the flue pipe.You must remember to put duct tape on the joints to prevent this from happening!

Those are the notes I compiled - from previous user errors.

Supposedly the reversed drill problem has been fixed in the design - but just to be safe I will not test it out. haha.

Rods are constructed of 12 mm nylon and are flexible enough to handle multiple elbows while the small bullet head design easily maneuvers through tighter spaces often found in liner venting systems.

Someone just told me they've used theirs for five years now - no problem.

The black rods are the ones "in stock" locally but they can not handle the 90 degree elbows.

Rods are constructed of 16 mm polypropylene

Nope - too rigid. I mean some people can do it but some people can't. There's complications sometimes.

So it's possible for sure.... but these are the ones I ordered:

So one hand and it bends even more!!

So that means I should get the 90 degree elbow and the sooteater by the end of the month for sure - if not in just a few days.

The reviews are more for a slightly higher priced version - so they must have posted a reduced price version that I ordered.

Someone says that the drill is better if it is corded since you get more power - otherwise the brush can get stuck in the creosote.... I haven't used the wood stove that much and I burn a hot fire regularly to hopefully burn off any creosote build up.

Could not spin the brush very fast or the line would shake too much. Found out why it is recommended to clean from the stove up. It is easy to drop the rods down the flue before they are all put together. But, it is less messy going from the top down. Just close up the stove and shut down combustion air and no crap got into the house.

Yes the whole point is that there's a flue cap on the top of the chimney pipe - and with a mesh around it to stop any potential sparks. I didn't realize that the mesh was really to keep out birds!!

So by going from the bottom up - then there's no need for me to dismantle the chimney flue cap - the rain cap is taped onto the duct pipe that is covered by rockwool insulation and another pipe plus with the mesh.

I inserted the entire length of the brush and started the drill moving up and down in about three foot strokes, removing one section each time I moved down. The system worked great, the sections locked together securely and unlocked easily when removing sections.

So everyone says this product only works for number 1 and number 2 creosote.

So then I bought "Creosote Destroyer" that is added into a medium fire - to then dry up the number 3 creosote. The number 3 creosote then falls off easier and has been converted to number 2 cresote.

Acts as a catalyst and destroys the binder which holds the creosote particles together.

Twice a week, with a good fire going, I'll throw two spoonfuls of this onto the hot coals. The next morning then things have cooled off, I can see what was a dark suet on the interior stove walls is now light gray and flaky. Not a substitute for cleaning the chimney liner with a brush every fall, but now that I use this, it's all just inert and flaky residue that falls out, not that sticky, combustible creosote lining the chimney like it used to.

So then I will detach my 30 degree stove pipe -

You can see it angling off to the right here. And I will replace that with the new Stainless steel pipe that I just put duct clamps around to make sure the lock seam holds.

The stainless steel remained hot the longest, showing the most thermal inertia...due to the longevity and corrosion resistance of stainless steel, they are likely to be a much better value in the long run....With one of the lowest thermal conductivities for a metal alloy, stainless takes much longer to conduct heat away from a source

So it's gonna heat up slower but lose heat more slowly also. Should be interesting.

Those were about $2.50 each.... so I got four of them and each holds 40 pounds of pressure.

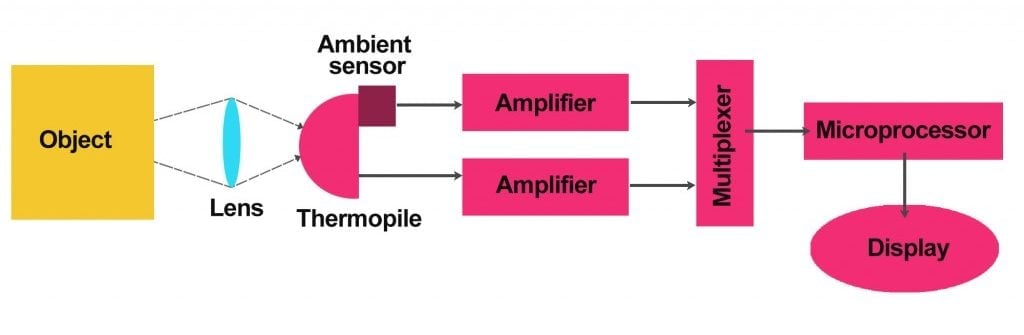

Then I got an Infrared Detector laser thermometer gun that goes up to 750 degrees. This way I can test to see how much heat extraction I am getting off that 30 degree stove pipe with the newly added "heat exchangers" on them.

So I'll put those on the 30 degree 4 foot stove pipe going towards the side wall.

Plus I'll add an Ecofan on top - directed at the heat exchangers - as recommended.

So then I will fill the 4 gallon stove pot full of water as water is the best for thermal mass radiation. Plus I have bricks surrounding the sides of the stove.

So the idea and goal is to increase the internal fire box temperature for a cleaner burn and hotter temperature. Then to increase the heat extraction from the stove pipe after that hotter temperature leaves the stove.

Lowering flue temperatures below 250 is always a bad idea. I would stay away from such contraptions, due to creosote build up.

The top BACK of the stove should be better insulated so that it doesn't over boil the water so fast - as there will be two ceramic fiber board baffles inserted plus the back wall as ceramic fiber board.

So the secondary air should burn off gases BETWEEN the two ceramic fiber boards - and create enough positive pressure expansion to then pull in the primary air from the bottom front of the stove.

So I should get a more thorough burn of the wood with less charcoal left over - and a cleaner burn that is hotter.

The stainless steel stove pipe can handle the slower 30 degree angle draft - with the hotter temperature - whereas the crimp on the galvanized duct pipe would not be able to handle the increased pressure from the increased temperature expansion.

With the Infrared detector then I can make sure the exhaust is hot enough to not build up creosote as well.

So the Infrared Detector Gun says it doesn't work if the object is highly reflective! I knew this must refer to "emissivity."

Stefan-Boltzmann law

The knowledge of infrared radiation being emitted by humans and animals has mostly been employed for thermal imaging. An infrared thermometer takes this a step further and puts a number to the amount of thermal radiation given off. IR thermometers do this by employing the Stefan-Boltzmann law.

The law states, ‘The thermal energy radiated per unit surface area per unit time by a black body is proportional to the fourth power of its absolute temperature’.

Mathematically,

E ∝ T4

Here, E is the radiant energy emitted per unit area per unit time and T is the absolute temperature of the object.

Upon removing the sign of proportionality, a constant term known as the Stefan–Boltzmann constant (σ = 5.67 x 10 –8 Wm –2K –4) gets added to the formula.

E = σT4

The above equation relates radiant energy to the temperature of a black body, a body/object that absorbs all radiation incident at it. However, a perfect black body doesn’t exist yet (although Vantablack comes pretty close), so the above equation must be adjusted for all other regular objects.

E = eσT4

The formula is modified by adding a term called emissivity (e). This is the ratio of radiant energy emitted by a regular surface to the radiant energy emitted by a black body surface at the same temperature. Emissivity values range from 0 to 1. An emissivity of 1 represents a perfect black body and 0 represents a perfect reflector. Human skin has an emissivity value between 0.97 and 0.99! (Source)

https://www.scienceabc.com/innovation/how-does-a-temperature-gun-infrared-thermometer-work.html

The laser, however, doesn’t have any functional use, nor is it the thing that actually measures the temperature. The laser is only present to help accurately pin-point/aim at the object to be measured.

Ah - that answers my question! Fascinating.

When I removed the top, (very simple, three small bolts, two front one rear), I discovered that the insulating blanket over the baffle was covered in almost two inches of ash, severely affecting the ability of the stove to draft. I am a heavy burner; continuous from late September through to May, six to seven cords. A few minutes with the shop-vac cleared all the ash out. A local metal fabrication plant is going to sandblast off the top's enamel finish and powder coat it. A far tougher, industrial finish, much better than Jotul's brittle enamel. A lesson well learnt is that maybe I should remove the top every three years and clear out the ash, replacing the gaskets at the same time.

No comments:

Post a Comment