304SS Sch40 - Pipe Nipple (Both Ends) - 1/2" MNPT - 24" L

.jpg)

So I ordered the stainless steel pipe from one company.

I ordered the 90 degree elbow from a second company since it was "in stock."

CALBRITE S40590EL00 1/2" X 90 SS304 STAINLESS STEEL ELBOW

304 Stainless Steel Material; 0.622 Inch Inner Diameter X 0.84 Inch Outer Diameter Size; Conduit Used on; Threaded Male Installation; Ul/Cul 6A/E230584, CSA C22.1 Approval; 1/2 Inch Trade Size; 90 Degree Bend Angle; Finish Bright Polished

I ordered the Coupler from a third company since it was not on the 1st company site....

Coupling: 304 Stainless Steel, 1/2 in x 1/2 in Fitting Pipe Size, Female NPT x Female NPT

So the goal here is to get secondary air that is preheated along the bottom of the wood stove - then UP to the back top of the wood stove to create enough extra oxygen needed to burn off the wood gases above the ceramic insulation fiber board baffle.

Why? Because the 1 inch baffle will be put in above the steel baffle and thus restrict the air flow to the back top of the stove.

I'm not sure at all IF the 1/2 inch stainless steel pipe will FIT through the primary air hole opening on the Two Dog stove.

Let's see if I can get some dimensions.

OK so I will have to cut open or possible just bend open that bottom screen that is welded on there.

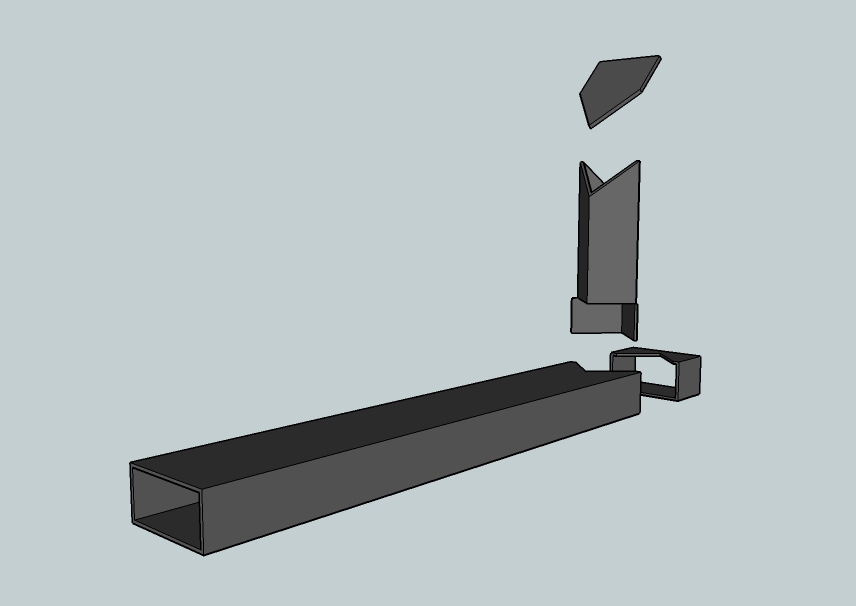

So the idea then is just insert the pipe in as a "P channel"

What's a "P channel" you ask?

OH well you need to be initiated into the arcana of the mass heater Batch Box Rocket Stove "scene."

The "P Channel" stands for "Peter Channel" because a Dude named Peter "invented" it.

Let's see if I can get an image.

Right - so he wants you to weld that up all yourself but I don't do welding.

So I ordered from THREE different companies to make sure the parts were in stock and hopefully it will fit together!! I'm pretty excited.

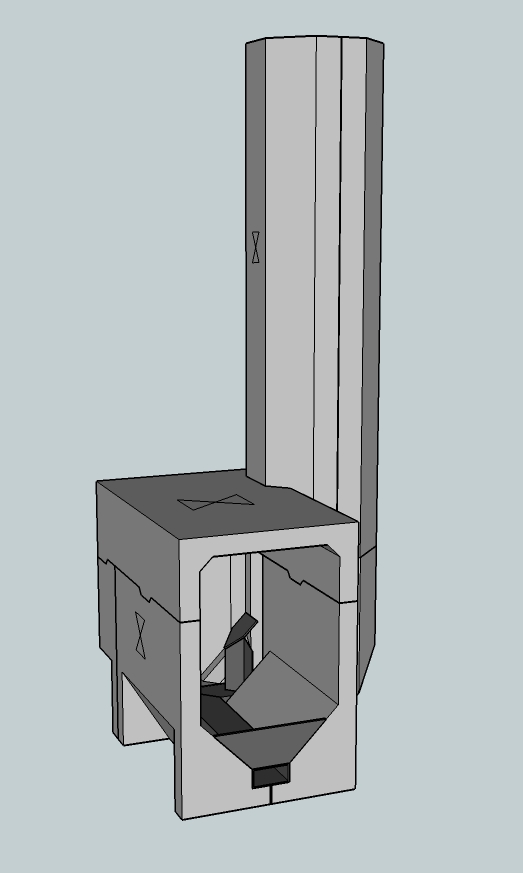

So that's how the "P Channel" looks in that Batch Box rocket stove.

So instead I will try insert my stainless steel pipe elbow in through the bottom hole of the wood stove to act as my P channel.

. I decided to use an S-Portal to feed tertiary air into the throat of the stove.

The S-portal can have any shape and is positioned vertically in one of the sidewalls of the firebox.

Actually, you need a door with this. The air is drawn from the front of the stove and led to the portal. The whole idea is to run the stove with much less excess air than usual.

Ecco stove - I might try a similar Tertiary baffle system.

So I would put in a SECOND layer of ceramic insulation fiber board above the first baffle - to channel the secondary air through the two baffles.

So that way the "ceramic insulation fiber board fire box" will be only for the combustion gases and NOT the actual fire wood!!

So that's the Harman "Firedome" afterburner and it is Ceramic Fiber board!!

JUST as I was imagining!!! A double chamber of ceramic fiber board!!

Everburn stoves like the Lopi Leyden and Harman Firedome stoves use a variation on this technology, routing the hot wood gas through a ceramic maze, but without the honeycomb.

My theory is that near the end of the burn cycle, the flue gasses just aren't hot enough to pull all of the smoke out through the afterburner.

The prob temps really depend on the stage of the burn, had it well over 1200 degrees and when I get to behave I can see 600-800 on small loads.

It can go up to 500-700F within minutes of the afterburner kicking in. (Also amazing how cool it is when you are NOT burning smoke, like 250F.) That's with mostly small fires and low air.https://www.hearth.com/talk/threads/harman-firedome-tricks.56906/page-2

Tonight I have conditions similar to the ones you mentioned: no wind and a 30 degree outside temp. I shut the bypass after 5-10 minutes open with full air on a hot reload, really blazing. With a half-load of very dry medium oak splits, I then left the air open halfway for about 15 minutes, by accident. Normally I would step it down to near zero air by then. Sure enough, I hit 800F in only 15 minutes- wow!

IF you have a dark room when it is going through that phase of burning, you can see a faint band of red when you are at 850 degrees. That is defined as over-firing.

But it is too bad Harman won't acknowledge to you they've made a stove that reaches borderline overfire by design. I hit 825F on the back-side this afternoon without even trying - a small load with less air than usual, and away it went.

Professor Richard C. Hill's patented ceramic afterburner system!

The products of combustion left the chamber and passed through a narrow ceramic neck which reached temperatures of 2000 degrees F where the gases and tars released by the wood completed their burning.

The burn tube connected the two pots is 12 cm (4.75 inches) in diameter and 26 cm (10 inches) long.

Fascinating!!

http://www.noutilitybills.com/Heaters/Wood/VC/VermontCastingsNonCatalyticWoodHeaters.html

Many producers are installing chessey ceramic baffles in the woodstove on the market. There are some (lopi, PE, jotul, woodstock) that still stick to steel, cast, and or bricks in their baffle which hold up to impact, but many out there do not. Napoleon, archgard, englander, hearthstone, dutchwest, regency, enviro, vermont castings ( the list goes on ) have a thin ceramic board which punctures easily and flakes off chunks within a year of use.

https://www.hearth.com/talk/threads/the-cheese-they-try-to-put-in-stove-now.34614/

By that time, Napoleon (Wolf Steel) had replaced the firebricks with these cheesy light panels. After this replacement, the stove's operating temperature went up by about 100 degrees with the same burn time. Why? Because the cheesy refractory panels improve the secondary performance enough to generate that much more combustion and heat.

Pacific Energy has a steel baffle underneath their ceramic fiber board!!! vid

Secondary baffle is built into a stainless box with ceramic blanket on top, then a stainless top cover.

My flue temperature is hovering right around 700 degrees.

Why don't they make integrated iron/ceramic baffles to provide better durability and faster light-off of the secondaries?

Seems like you mainly need ceramic thing for the fast light off - so just line the baffle area with some ceramic. Doesn't need to be supportive. Hell, if the ceramic breaks/chips, no big deal - it'll still operate, just won't light off quite as fast.

https://www.hearth.com/talk/threads/the-cheese-they-try-to-put-in-stove-now.34614/page-4

2 piece cast iron baffle with insulation on the top.

The two pieces pop, ping, and move a bit when the stove gets up to temp.

No comments:

Post a Comment