At just 1,800 rpm, 90% of the Vortec 4200’s torque is at attention, tugging better than any V-6 we’ve tried.

https://www.wardsauto.com/news-analysis/general-motors-vortec-42l-dohc-i-6

This car is very "torquey" -

torquey - Wiktionary

(informal, automotive) Producing a large amount of torque

So Torquey is an actual real word! Albeit informal.

https://www.drifted.com/four-two-vortec/

enabling GM to provide similar power figures to its V8 rivals in a six-cylinder package.

As the engine began to achieve soaring popularity, it also landed a spot on Ward’s 10 Best Engines list for three consecutive years from 2002 to 2005.

the exhaust camshaft timing has a range of 25 degrees, depending on the engine’s operating conditions.

This is what fascinates me.

the phase angle of the camshaft is rotated forwards or backwards relative to the crankshaft. Thus the valves open and close earlier or later; however, the camshaft lift and duration cannot be altered solely with a cam-phasing system.

I was just reading a Do It Yourself manual from the 1970s - discussing variable displacement - and I think this must also refer to this.

Variable valve timing and variable displacement systems have been on the road and continuously evolving for years. They go by a myriad of different names including Toyota and Honda VTEC, GM Cam Phasing, GM DoD (Displacement on Demand

https://www.vehicleservicepros.com/service-repair/the-garage/article/21182884/its-all-in-the-timing

the intake cam lobe may allow its valves to open as early as 48 degrees Before Top Dead Center (BTDC) on the exhaust stroke and close as late as 84 degrees BTDC into the compression stroke.

GM’s earliest variable cam timing systems came out in the 2002 Trailblazer/Envoy models sporting an inline 6 cylinder DOHC engine. This engine applied a cam phaser of a splined gear design. The single phaser located between the exhaust camshaft and sprocket can vary cam timing by as much as 25 degrees (50 degrees crank angle). A spring applied between the two splined gears to hold the phaser to 0 degrees where a lock pin holds it in place after engine shut down.

sounds complicated!

OH so my 2004 year does NOT have "displacement on demand!!" fascinating.

When replacing a timing chain/gear set, camshaft or the cam phaser actuator, special care must be exercised. On the front of the cam sprocket/actuator assembly is a reluctor wheel held in place with three roll pins. Don’t pull on the reluctor wheel. Remove the sprocket by pulling on the sides of the sprocket while holding the reluctor wheel up to it and in place. When removed, hold these components together by inserting a plastic wire tie into the hole in the center to tie everything together. The actuator assembly contains springs that could hurt you or at least make a useless puzzle of the actuator should you disassemble the assembly accidently.

Diagnostic Trouble Code:

By far the most common problems revolve around lubrication issues. Owners who neglect regular oil changes or engage in continuous heavy-duty/high-performance engine operation are the most likely candidates for drivability problems and DTCs.

Yes we make sure to get the oil changed frequently. Every 3000 miles!!

By holding the exhaust valve open slightly longer, the cylinder is emptied more and ready to be filled with a bigger air/fuel charge on the intake stroke. By closing the valve slightly early, more exhaust gas remains in the cylinder which increases fuel efficiency. This allows for more efficient operation under all conditions.

right...

With the earlier engines approaching their twentieth birthdays, the sheer quantity of those still running problem-free is a testament to how reliable they can be when correctly maintained.

So we're at 17 years...

The VVT solenoid provides oil to the cam phaser, and if this becomes clogged or restricted, it can cause damage to the phaser.

OK we got ours replaced.

Wow - so an Engine Rebuild Overhaul kit is sold for around $600. Very interesting!!

It's the labor that would make this very expensive - probably $2000 in labor costs....

When it comes to off-the-shelf upgrades, the first components to consider are, as always, getting the engine breathing to the best of its ability.

Replacing the filter for a green filter

This is precisely what I did - only an AEM Dry Filter and YES there is a definitely noticed improvement in horsepower.

With many owners now running beyond 250,000 miles without significant issues, it’s a true testament to their reliability when correctly maintained.

Let’s not forget that the Atlas range was designed as a low-revving, high-torque truck engine, and with almost full-torque being reached at just 1,800 rpm, it achieves its task perfectly.

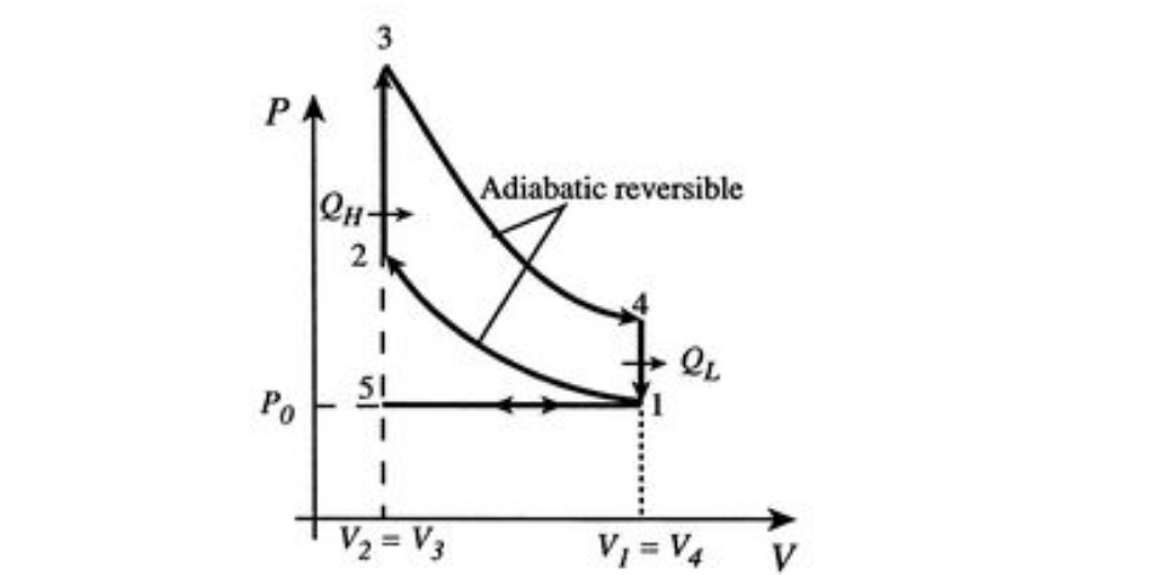

The area within those 1-2-3-4 lines represents how much work done by the engine. Higher compression ratio means the two vertical lines on the plot will move to the left and up, leaving more area within the bounds than with a lower compression ratio, and thus work being done.

so...

Along with being naturally balanced, an inline engine only has one cylinder head, which lowers cost

Twin overhead camshafts were used to control the exhaust and intake valves separately. Furthermore, GM’s first stab at variable valve timing was put into place on the exhaust side. This allowed the engine to breath deeper during high-throttle situations, resulting in higher power without the fuel consumption penalty being present throughout the rev range.

Both cams were operated via a timing chain with a hydraulically operated tensioner. When running, oil pressure is sent to the tensioner, which keeps the chain tight throughout its lifetime.

Ah hence the need for oil in very good condition.

This early adopter only had VVT on the exhaust side, however, but allowed for 25 degrees of exhaust cam phasing. This kept torque levels at near-peak levels throughout the rev range and allowed a higher maximum horsepower without killing fuel efficiency or hindering drivability at lower rpm levels.

OH so that's how it works! Fascinating.

The cam would then rotate relative to the cam sprocket, creating the different camshaft profile, which changed the timing of the exhaust valves opening.

https://www.compcams.com/valve-timing-tutorial

Since the camshaft turns at half of the speed of the crank, the power stroke only sees one fourth of a turn of the cam, or 90 camshaft degrees.

If the overlap phase occurs too early, it will create an overly rich condition in the exhaust port, severely hurting the gas mileage.So the Vortec 4200:

it can only retard exhaust cam timing

The helical spline/piston is controlled hydraulically. Engine oil is directed by a control valve to the appropriate passage in the phaser, turning the camshaft relative to the sprocket. At idle, the exhaust cam is at full advanced position for minimum intake valve overlap. This provides exceptionally smooth idling. Under other engine operating conditions, the phaser is controlled by the Powertrain Control Module (PCM) to deliver optimal exhaust valve timing for performance, driveability, and fuel economy.Just as with the original VVT Fiat system!

Pulse Width Modulation) is an efficient way to vary the speed and power of electric DC motors.To do that, an onboard computer first collects several points of data including throttle position, engine load, and vehicle speed. From there, a control valve adds or removes oil from a cavity and piston chamber (see cutaway photo) at the front of the camshaft.http://www.superchevy.com/how-to/83758-chevrolet-vortec-4200-inline-six-engine

12.5 degrees of Retard at 3000 RPM.... is how the OEM computer is for the Vortec 4200...

No comments:

Post a Comment