1x6 with conduit clamps

So this was a great comment - vid

So this new spark arrester finally arrived to the U.S. from China - yesterday!! Should be here from the West Coast within a week....

That is for the new tent stove that is collapsible for portable winter camping.

OK so now to the "permanent" campsite plan for Eco-Echo mini-forest.

Here someone adds with wood - for reinforced extra framing - vid

So what I'd like to do is use local wood - willow - in say five years - after they grow in more. Primitive Structure Garage - as I posted before.

|

| temporarily held by vise grips |

Wow - so he's a really long screw to go through the vertical wood 2 x 4 AND the vertical metal tube - with a "hole" in the 2 x 4. Pretty wild design.

So he is mimicking the same exterior and interior dimensions of the steel pipe via the 2 x 4s using holes in the 2 x 4s....

very interesting design!! Still a "wattle wall" might serve a similar purpose to support the structure. Then just cob the outside with a lime plaster stucco!!

I already used lime for my access driveway and it's worked great so far. I just mixed in some barn lime with quick lime or whatever - and some mortar mix and gravel. Just a DIY mix.

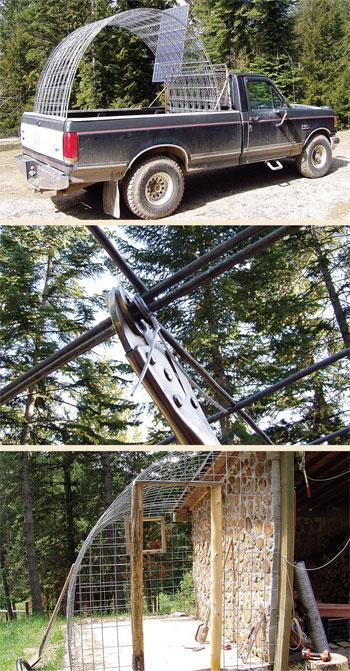

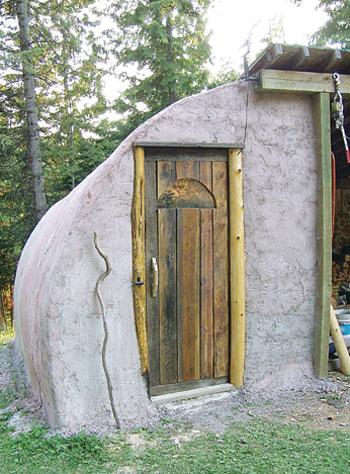

https://www.backwoodshome.com/building-a-ferro-cement-shed/

This is basically a thin shell of cement embedded in a wire frame. Cement is very strong in compression but is brittle and has no strength in tension. A thin steel rod or wire is very strong in tension, but weak in compression and will bend.

https://www.landmsupply.com/ok-brand-16-x50-select-cattle-panel-0060-0

I could have saved a LOT of wattle by using this before. haha. Just double it up. But harvesting and building willow wattle was "fun"? haha.

Never heard of it!

To prevent too much cement from dropping through, I used 2.5-pound plastering lath on the inside of the cattle panels and one layer of chicken wire on the outside. This lath is light-gauge galvanized expanded steel. It is ideal for holding plaster, but costs substantially more than chicken wire.

waterproofing and weather resistance he recommends a 1 to 3 Portland cement to sand mix for the first layer, then a ratio of 2 to 3 or even 3 to 5 for the outer layers. This will give greater strength and be as waterproof as a concrete pool. In a structure with a roof of cement, the material needs to be as impermeable to water as possible. You could add one of the new acrylic concrete fortifying products to improve waterproofing and adhesion, at least in the finish coats.

At one point, the weight of the cement started to buckle the cattle panel frame. Past that point, the frame needed to be shored up on the inside. I had thought the stiff bow of cattle panel would hold the weight, but cement is very heavy.

This job was big enough to merit buying several 50-pound sacks of powdered gypsum plaster, and mixing 50/50 with sand and enough water to make a nice, thick mud.

OK I should do that on my shed-hut walls also.

gypsum plaster is safe, non-toxic, and easy to use. It sticks well to surfaces, doesn’t crack, and anyone can have fun smearing it on a wall for a nice textured surface.

a masonry supply store can special-order it for you.

I mixed lime and water in a bucket until it looked like milk, then brushed it on the plastered walls.

Since the structure still wasn’t sufficiently waterproof, we applied a layer of Quikrete masonry coating to the outside. This stuff is sold in 20-pound pails, mixed with water to the consistency of thick paint, and applied with a brush. I reckon it’s made of Portland cement, fine sand, and a waterproof binder, probably acrylic.

Wow so I looked up the author since he said he was going to do a follow up cabin or hut based on the same style and he left his body a year later!!

OK so I could just do the walls this way.... And a lighter roof. Still don't want to use metal - too loud. So... I wonder if I used tarps - the poly-canvas heavy duty as I used for the shed-hut. But then I cover them with something for UV protection.

you might want to stabilize the second coat with a bit of Portland cement or emulsified asphalt to make it more durable. No matter how you organize your plastering, I would still recommend using tarps to keep the bags covered until they can be covered with a plaster, except for the area where you are working.

http://www.earthbagbuilding.com/faqs/uv.htm

Cool - newly designed asphalt roof tiles as roofing panels?

https://www.youtube.com/watch?v=7nbj_BwIDgU&feature=emb_logo

installation

everyone hates it - says it looks sloppy!

I LoVE sloppy! It's primativist!!

https://swiftfoundations.co.uk/watershed-roofing-kit/

- Guaranteed against weathering for 10 years

- Install with the smooth side uppermost

Asphalt Roll Roof

OK so this is what I want....

7/16 OSB plus asphalt roll roof vid

Mid-States Asphalt 3 ft. W x 36 ft. L Asphalt Mineral Surface Rolled Roofing 90 lb. Black

$60

This product was easy to install and looked great when finished. A week later I walked on it during a 90 deg. day and was leaving foot steps in the material. I quickly left and came back on an 80 deg. day- same thing. I waited for a 73 deg. day and did not have the same problem. I have been purchasing roll roofing from HD for 15 years and never had this issue on any temperature day. I am concerned that this will not hold up. I would not recommend this product unless you are about to sell your house immediately. Make sure the inspector comes on a cool day. Not worth the savings on this cheap product.

So it lacks the "adhesive" but it might be easier to work with for that reason?

I wonder if there is an eco-friendly adhesive?

The reason I rated this product 4 stars was due to the difficulty experienced when installing it beneath a hot summer sun, at which time the plastic backing is extremely difficult to pull off and the adhesive underside becomes extremely sticky and difficult to position and re-position. In contrast, installing this product in the early morning or early evening, or during periods of cloud cover is very easy - the backing pull off easily and the sheets can be positioned and re-positioned with no difficulty.

So that's the self-adhesive "Weatherwatch" asphalt roll

I purchased two rolls for a small project. I have never been so frustrated installing this material is very sticky and will not allow for correction. I gave up on using this material as the backing got stuck and would not come loose no matter how hard I tried.

Torch down roofing (sometimes referred to as “torch on” roofing) is so named because it requires an open-flame propane torch. In this installation method, sheets of modified bitumen are rolled out onto the roof, and a roofing professional uses a hand-held propane torch to heat the material and adhere it to the surface.

https://www.infiniteroofingny.com/commercial-roofing/modified-bitumen/dangers-of-torch-down-roofing/

Ideally suited for residential low-slope applications such as porches and carports or as flashing materials

EasyStick Plus™ Black Self-Adhered Rolled Roofing 36" x 36' (100 sq ft Coverage)

Tarco LB323216 Easy Stick Plus, 3' x 36', White, 1 Square Roll Roof Leak Barrier, Square Self Adhered Mineral Surfaced Roofing SBS Modified Asphalt With Polyester Inner Mat, 10 Year Warranty Direct To The Decking,

$100 - polyester asphalt combo - very interesting!

OK I emailed the Tarco folks to see if that Poly-asphalt adheres to poly-canvas. haha.

$60. This might be better than Weatherwatch or whatever.

Liberty 3 ft. x 34 ft. (100 sq. ft.) SBS Self-Adhering Cap Sheet Roll for Low Slope Roofing in Black

Ok I forgot about breathability.

Deck-Armor 400 sq. ft. Premium Breathable Synthetic Roofing Underlayment Roll

but what is it?

Polypropylene

https://www.lowes.com/pd/GAF-Deck-Armor-48-in-x-100-ft-400-sq-ft-Polypropylene-Roof-Underlayment/50404476

how is that breathable? OH it's a WEAVE aka spun-bound design. Very cool.

Helps prevent inside moisture from becoming trapped within your roofing system causing mold, mildew, and expensive structural damage

Provides longer-lasting leak protection than conventional felts (which can rot or become brittle before your shingles reach their useful life)

Unlike conventional asphalt felts, resists wrinkling or buckling, so it lets your shingles lay flatter for a better looking roof

Exceptionally strong: greater tear strength than standard #30 felt

Long-lasting protection: up to a lifetime limited warranty when installed on lifetime shingle roofs

Special slip-resistant surface provides enhanced walk ability, even on steeper-pitched roofs

Light blue surface is cooler in hot weather than conventional black felts

Spun-bound design is easier to cut than some other synthetic products

Deck-Armor is neither peel and stick nor self-adhesive.

good!!

I think this is the best.

So this is underlayment but the same company also makes Weatherwatch:

GAF’s WeatherWatch® leak barrier takes leak protection a step further than competing products. It’s reinforced with fiberglass to prevent buckling and wrinkling. It self-seals around nails to create a waterproof, gap-free barrier.

OH I get it - the underlayer can not handle UV either.

unroll it where you want it and let it sit for about 15 minutes (to acclimate to laying flat), then slip the backing out from underneath and it's stuck down! Much better than traditional felt and only nails required are 18" on top edge. Apply to dry sheathing and it is good weatherproofing for up to 90 days

OK so I can use Silicone for UV protection.

https://www.roofcoatingsupply.com/GACOROOF-100-SILICONE-ROOF-COATING-p/gr1600-col.htm

$225 on sale - says it covers 250 sq feet for two layers.

So instead of paying a zillion then I just get the Silicone Caulk and mix it into odor free mineral spirits and spray on to roof? It should evaporate off?

GE Silicone 2 does NOT have acetic acid!! Wow.2 is ammonia. It has an odor, but not overpowering or eye watering.

https://www.youtube.com/watch?v=Vc9bhM2b0vE

make sure it is WATERproof not "weather proof" (i.e. paintable)

No comments:

Post a Comment