So then I will get increased temperatures of a typical masonry stove and then I will surround that "double" batch box (again as per the previous image posted) - with the brick (clay-sand mortar).

So then I have a grill from a Craig's List free grill pick up - that I will use for the "base" of the stove.

So then the air intake will be below that grill - with no secondary needed since there will be no heat riser in the back.

Oh I just realized - I can use the SIDE channels via the grill as a secondary air feed - through a side tunnel.... (maybe). I need to test the draw I get from the chimney - if it overrules the side tunnel from BELOW - then it should work!

So then - I still need to make a door for the whole thing - so I have to extend the front a bit enough (with a foot brick system) - so that the door can cover up the stove entrance). https://permies.com/t/71575/Casserole-Door-innovative-door-batch

I don't agree with the notion that batch rockets are no good without a proper door. Air flow in a well-running J-tube need to be restricted with a couple of fire bricks. Nobody is objecting to that, so it's as good a solution when used for a batchrocket. Two more bricks and you'll good for to close off about 3/4 of a 6" batch box rocket's front opening. Done that many times, none of my development projects had a door, I used bricks or a combination of a glass piece and bricks.

So this will be similar to the Kang bed stove only that instead of a horizontal bed that requires an inside insulated chimney, I will have a vertical "bed" (masonry heat sink).

So then the chimney can go outside and I can insulate it with rock wool on the outside.

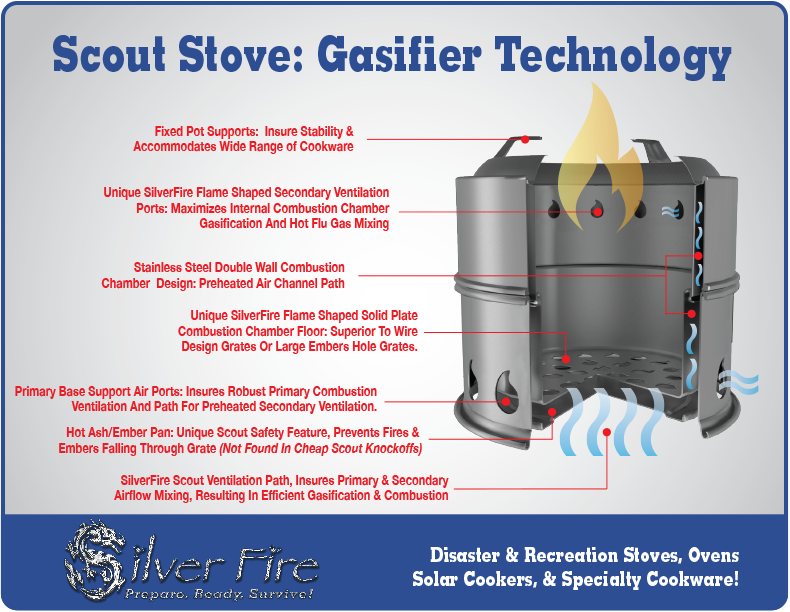

Rock mineral wool insulation is superior to cheap clay insulation or tiles, period.https://www.silverfire.us/survivor-rocket-stove-p10

So I will be "mimicking" my Silverfire Survivor Rocket Stove - only as an enclosed mass rocket stove. Maybe I should use rock wool also for the batch box? I need to look that up.

Joining up four pieces of the stuff seemed much easier than doing something with perlite and slip too.http://donkey32.proboards.com/thread/1249/roxul-board-riser

The ComfortBoard FS variety seems to have a melting point of 1177 degrees Celsius. I fully expect it to withstand when used as the higher part of the riser in a batch box system. The lower part of the riser just behind the port looks like a bit too violent environment for this material.

The adhesives used to hold rock wool together don't whistand the heat. I've tried the same from rockwool.

you should go with ceramic blanket rather than rock wool. Ceramic blanket can handle higher temperatures.https://permies.com/t/29455/Rock-wool-Mineral-wool-Insulation

Rock wool is thermally insulating because of the air trapped between the rock fibers. The fiber itself is not insulating. It has a similar thermal conductivity as the rock it was made of. The task of the fiber is to prevent air from moving round (convection). Moving air would transport heat from hot surfaces to cold ones. This means it would be better if the layer of rock wool would be enclosed in an airtight coat to prevent any air going in and out the rock wool layer. That's one of the reasons (besides reflection of thermal radiation) I drew an outer layer of aluminum foil in the sketch. Ok - this effect might be small. If the rock wool layer is thick enough there is enough air in the middle of the layer that can not move anywhere.

Also Stonewool and expanded pellets have about the same heat point; over 2000 degrees F, but the insulating wool for building is very different than the horticultural medium type- it has a binder and is infused with oil to make it water resistant. I don't know how the burning off of all that would affect it structurally, (I doubt in any way that make it melt thereby compromising it) but it would probably smell really bad, at least at first so something to consider...https://www.resilience.org/stories/2016-02-08/it-s-not-rocket-surgery-choosing-an-indoor-mini-wood-stove-for-a-tiny-house/

Wow - excellent reviews of stoves - and covers the Hunter Silverfire stove that I have already (and installed in the teepee)....

https://fourdog.com/two-dog-stove-dx/

So that above article neglects this Minnesota-Made stove. If my above plan fails then I can go drive to pick up this stove.

Rocket mass heater out of a wood stove vid

So if I build one - then I can not MOVE it for winter camping elsewhere. If I build it - I still have to figure out a door situation. Best to buy the Minnesota made stove - go pick it up. Then just put bricks around the stove. I might even still use my chimney brick configuration that I posted last. The Kang Bed - stove configuration. Probably not though.

OK I did it - I just BOUGHT the "FourDog" Minnesota Made "two dog" stove. This is a portable stove so that I can use it camping in the national forest - if I need to do so - to get a tent silicone protection with a canvas. I will have to make such a winter tent.

Two Dog stove in a tent vid

It did radiate heat longer than if it was just the steel alone but essentially it took a long time to release that initial heat because your heating the metal and then brick or whatever you choose to use as mass . I could put my hands on the bricks and feel the warmth but if I removed one from the stove the steel was scorching underneath .Most heat went straight up the chimney unfortunately .I ended up using the top of the stove as a mass storage for heat which made it safer for my cats who dig it 😸but left the sides alone to radiate the immediate heat . All that aside comparatively speaking regular wood stoves are such a waste of potential energy and are so inefficient it's unreal ,plus they're extremely dangerous . A good friend of mine almost died because of a creosote fire . That's also the beauty of the rocket stove design,no creosote build up at all.http://www.small-cabin.com/forum/2_1616_0.html

Just got back from installing the "2 Dog" wood stove. It went great, after some modifications.

It was zero degrees outside today, but the stove easily heated the place to mid-60's, without us feeding it any seriously large logs.

The stove burns very hot, especially on the sides. Our clearance ended up 18" in back and 12" on the side. there's a 1 inch gap between the wall and 1/2 inch cement board (all the way up the wall), and then a 1.5 inch cement tile board. The backside wall never got too hot even to the touch. The side wall at 12" got VERY hot the first night, so we extended the cement board all the way up the wall, bought 2 half-sized concrete blocks and moved the 1.5 inch cement/ tile board up the wall. Did the trick.

We also learned the stove doesn't need much to get hot. We overdid it the first night and ended up with some smoke in the cabin. We learned to use fewer and smaller pieces of wood.

Let me know if you have any specific questions about the 2 dog. I HIGHLY recommend it. Our cabin is 10X12 and it works perfectly for us

No comments:

Post a Comment