So then I put on willow cross beams - length wise. I saw some good tall thin willow trees. So they are maybe 2 inch diameter or less. Hopefully more like 1 inch to 1 1/2 inch diameter.

So then I get another Silicone tarp - like the one I have over my tent....

Yardworks® 10' x 12' Green Industrial-Strength Tarp

This is how they are "branded" by Menards (Midwest DIY big box store)...

https://www.tarpsnow.com/waterproof-canvas-tarps-breathable-tarps.html

This is the actual tarp - it is breathable yet waterproof.

Also there is no noticeable toxic smell. It's silicone.

So also stands up to cold weather.

So Menard's price is actually cheaper than the website price - maybe that's due to shipping.

Sure enough!! "Mytarp" sells sheet metal screws to fasten their tarps to wood or metal!!

The turn snap button first needs an oval shaped turn snap button washer installed on tarp. After the turn snap button washer is installed on tarp, install the turn snap button on frame or wall where tarp is fastened to. Finally, thread the turn snap button through the special turn snap button washer; turn the turn snap by 90 degrees and lock the turn snap fastener in securely place.

Oh just as I suspected - it's a special pre-made grommet system.

So this is to stop the tarp from tearing...

But they want $50 for 10 packs with 25 in each pack?

So do I need 250 of these? Oh and you also have to buy the grommets! $4 for 10 of them? So if you want 250 you need $100 for those? Crazy expensive....

PLUS a "hole punch" and a driver or drill bit?

OK I think I'll just risk the tarp tearing. What I will do is put Duck Tape at the spot where I will drill the tarp. That should protect the tarp from tearing.

So I buy TWO tarps.

So the first one I put on top of the rafters. Then I drill in the cross beams into the tarp - oh but I want the rubber washer - I have to drill ... the washer is supposed to be against the tarp.... I guess it doesn't matter since the rain or snow is from above anyway. OK....

So THEN I put the Rockwool insulation against the cross beams - that again are 1 1/2 inch high. How thick is that rockwool and if it gets "compressed" - will it still work?

OK I can get 2 1/2 inch sealing screws - can I just get rubber washers to fit my 2 1/2 inch screws?

#9 x 2-1/2 in. Hex-Washer-Head Sharp Point Roofing Screws with Washer (60-per Pack)

OK so it's $12 for 60 - so that's ok price...

OK so I got 2 1/2 inch - so that means my cross beams can be 2 inches say - and so what size rockwool can I get?

ROCKWOOL ComfortBoard IS 1-1/2 in. x 2 ft. x 4 ft ... - The Home Depot

https://www.homedepot.com/p/ROCKWOOL...IS-1...2-in...2.../206789748

Rating: 4.6 - 71 reviewsROCKWOOL ComfortBoard IS 1-1/2 in. x 2 ft. x 4 ft. .... R-30 ComfortBatt Fire Resistant Mineral Wool Insulation Batt 15 in. x 47 in ..... Product Thickness (in.) ...2" Thick 8# Mineral Wool Acoustical Board - Buy Insulation Products

https://www.buyinsulationproductstore.com/2-thick-8-mineral-wool-acoustical-board/

Roxul 2" thick mineral wool acoustic board is used to absorb high and low frequencies in studios and home theaters.

So I should be able to get this somewhere - I think the big box store only has the wall insulation which is a lot thicker. I was looking at and smelling it today but I did not measure it. I forgot how thick it is...

I think that says 3 inches - on the side of the package!

So I think I need "comfort board" - not "comfort batt"

yeah the smallest Comfort Batt is 2.5 inch.

So I want Comfort Board.

But I suppose the R-value is then less.

R-value of 4.

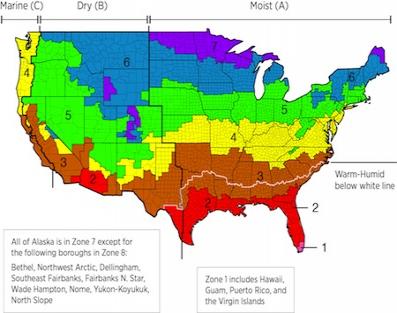

So I am in mainly Alaska building zone - it FEELS like Alaska in northern Minnesota. Maybe that's why I like it so much - reminds me of when I lived in the wild in Alaska for four months when I was 19 years old.

Of course abrupt global warming is going to drastically change these...and very soon.

So ideally I would need an R value of say 15 with a 3 inch - that's why the comfort Matt is what is sold locally. That's what i got for the tipi.

It's just I need to put the tarp over the insulation without crushing the insulation...

yeah even still - the snow will crush the insulation.....

So maybe I should use straw-clay on the roof as well?

They have fiberglass for their roof - with the clay slip for the walls.

So I need to put in cross beams UNDER the roof? so I can put in the insulation at 3 inches? hhhmmm.... I guess that is possible.

my straw is not chopped - I don't know if they chopped the straw in the bronze ages...

https://permies.com/t/46267I can take a board or batt of mineral wool and place it in a tank of water overnight and it is still in good enough shape the next day to place in a wall void....I would never do this with cellulose and even dislike the many "wet applications" that many contractors use to apply it.

I won't place a structure I facilitate closer than 600 mm to finished grade, unless specifically designed for such contact. Then the materials are all moisture tolerant (e.g. stone, brick, etc.) Traditional methods usually follow the same format and logic in design. This is the reason that a sawdust filled void would not be anywhere near the finished grade or "splash zone."So did the Bronze Age use a "wall Sill" also - a wood board along the bottom of the ground for the wall? I suppose so.... I need to double check.

the wall sits on a floating slab. The slab is isolated from the fill/sand/gravel/soil by 2" of high density styrofoam, so that breaks moisture creep up through the slab.

I laid 1/4" plywood in the void between the inner and outer base plates, so the cellulose never touches the cement, and under the plywood is 6 mil polyethylene.I think that's the Code Limit!! 2 feet for overhangs!!

Yeah, roof overhangs drive me crazy--when they are too small.

I built a mower/tiller shed, and it got 2' overhangs too.

So I could put the Rockwool under the roof - at the top - one roll - so the top of the room would get r-15.

I should be able to get 2 rolls wide - under the top center - so I loose - I just go along the rafters. This might work if I can figure out how to hang down another set parallel to the rafters...

Oh I'm suppose to put the plywood on top, then the insulation on bottom and then the drywall into the insulation!!? That's just like a "normal" roof?!!

I'm trying to think of an easier way! Those rafters are mainly almost 3 inches - so might fit most of the insulation...

Maybe I can put SIPs on top?

The spray foam in the cavities 17 years ago and the fully adhered membrane over the top. I just didn’t get around to doing the second part - rigid insulation over the top of the existing roof deck.1 Strip the shingles, expose the deck, install a fully adhered membrane and go to town with rigid insulation. How much rigid insulation? By this time I had it figured out. Nothing like two more decades of experience to draw on. I needed at least R-50 just to control the ice damming in my climate zone. Oh, yeah, forgot to tell you about ice damming. Wrote about the ice damming thing already as well (BSI-046: Dam Ice Dam). We didn’t actually get ice dams, but I think it was more due to luck than skill. Simple roofs don’t collect and hold snow. We had a simple roof. Anyway, to do it all, ice damming, comfort, noise and energy2—I figured at least R-60.Wow - R 70 to stop ice dams!!

If I already had R-35 I would need another R-25 which is about 4 inches of polyisocyanurate. So I added 6 inches. You all knew that is where this was going. I added another R-36 getting around R-70.3 Plus, I needed to prove something. Not what you think. Aesthetics. Huh? Read on. Besides, the cost of adding the extra 2 inches was nothing compared to the cost of the trim details and framing necessary to over-roof.

Awesome! So with rigid insulation I don't have to worry about it getting "compacted."

Problem with polyisocyanurate is it is NOT fire resistant!!!!!!!!!!!!!!!!

So I will "over roof" with Rockwool Comfortboard!!

https://www.rockwool.com/products/comfortboard-80/?selectedCat=comfortboard%E2%84%A2%2080%20downloads#Specifications&Sizes

It's kind of hard to figure out that site - says 80 as r-value but has different thickness?

439 psf (21 kPa) @ 10% compression

impressive!

hmmm - soR-Value per Inch: 4Thickness (Inches): 1.5Maximum R-Value: 6Width (Inches): 24

the R-value is not NEARLY as good as that polyiso stuff.... someone comments:

I was expecting a 20% to 40% premium for comfortboard but instead found pricing in the neighborhood of triple the cost per R per sf of foamboard of any type (depending a bit on your polyiso deration swag).and...

Installing 18″ of batt insulation in 4 layers is not for the feint of heart! The weight of the ROCKWOOL COMFORTBATT® worked against me in the cathedral ceilings, as the top layers would start pushing down the lower layers. If I was to do this again, I would ensure the roof trusses were just under 24″ spacing as this would create the friction needed to hold everything in place. Live and learn! Even those at exactly 24″ were marginal with the 4 layers, and if they were even 1/8″ to 1/4″ to wide, everything just fell out unless I found a way to temporarily hold in place.https://www.theenclosure.ca/wool-cap-complete/

Batts also require a 6 mil poly vapor barrier to be stapled or tacked to the studs over the insulation.So I can just staple or tack in a breathable vapor barrier....

First off, in all fairness to this product, it is being promoted as an exterior wall vapor barrier, not a ceiling vapor barrier, with the possible exception of a hot roof application.that's what the tarp will be!!

So Tarp plus insulation - UNDER the rafters...... then something hard over the rafters that won't compress? - The comfort board? Then a tarp over that?

Very Expensive!! https://plasticinehouse.com/how-to-insulate-a-shed/

Staple or tack the 6-mil poly vapor barrier to the ceiling side if the rafters. Attach your ceiling material so the insulation won’t fall through.

Fill the space between the rafters tight to the baffles, and then lay another layer of batts across the rafters. This will give 10 + inches of insulation and break the thermal bridge.

http://www.archiexpo.com/prod/eurovent-eurosystem-polska/product-72093-1024433.html

Very fascinating - Europe sells a POlyester vapor barrier but I can't find it in the US. Says it's perfect for roofing!!

So that is what I had planned on originally - the Silicone polyester tarp - both below and the insulation below - and then - put cross beams above to protect the insulation from compression. - so I can have 3 inch comfort batt. Then try put comfortBOARD on top and then another silicone tarp on top of that.

http://www.smallplanetsupply.us/heco-topix-therm-insulation-screw-4-7-to-17-75-inches/

Wow these are the specialized insulation screws - VERY pricey!!

The roof was built as a compact assembly using 16 inch deep I-joists for the structure. A 5/8 inch plywood roof deck was fastened over the I-joists, followed by a fully-adhered roof membrane, 4.5 inches of foil-faced polyiso to control thermal bridging through the I-joists, and a 2nd roof deck of 7/16 inch OSB sheathing. The OSB sheathing was protected with roofing paper, then finished with a standing seam metal roof. To the inside, the I-joists were insulated first with 3 inches of closed cell spray polyurethane foam, blown tight to the underside of the plywood roof deck, then 13" of netted, dense-pack cellulose insulation. An Intello Plus air barrier and vapor retarder was fastened to the underside of the I-joists, followed by 1x3 cross strapping for a wire chase and drywall. The R-value of the roof is approximately R-95.wow - MN sustainable house.

https://www.ecofoil.com/Radiant-Barrier-Perforated-4-x-125-500-sq-ft

Wonder how much this would increase the R-value?

http://www.startribune.com/whistleblower-radiant-barriers-show-dubious-benefits-in-minnesota/205029061/

Oops - stuff doesn't really work for cold climates! Busted.

OK so Limewash on top will reflect the heat - both ways....

https://www.grainger.com/product/ROXUL-2-x-48-x-24-Mineral-Wool-High-19NE78

So this is the RIGID Rockwool - resists compression.

Lightweight material is rigid, water repellent, and ideal where compressive resistance is required. Insulation has excellent thermal resistance, is noncorrosive, and chemically inert. Suitable for use in high temp. applications including drying oven equipment, petrochemical and power generating equipment, and storage tanks.I would need 8 of them at $20 each - very pricey!

I can get a half inch less - so then $13 each - so $120 (with tax)....

The Rhinotex branded Waterproof Canvas Tarps are crafted with 100 percent silicone-coated polyester and are 2-3 times stronger than the traditional cotton canvas tarps.So this is what I have....

Slip straw weighs ~13 lbs / cu ft ...the density of slip straw/ straw light clay is around 208 kg/m³.

how much can a tarp hold!! https://permies.com/t/54793/Straw-clay-attic-insulation

Clay slip best application is in a wall that is in direct contact with solid ground/interior space, and/or a ceiling/roof that has been designed to take the loads.

. I’d add 3/4" furring strips to mineral wool boards on rafters for an outer ventilation/ rain plain and outsulation board like mineral wool IS over them to stop thermal bridging. If I could not afford that I'd do another cast-in-place slip (clay or better lime is lighter) wet install layer at the rafters let it dry in.

No comments:

Post a Comment