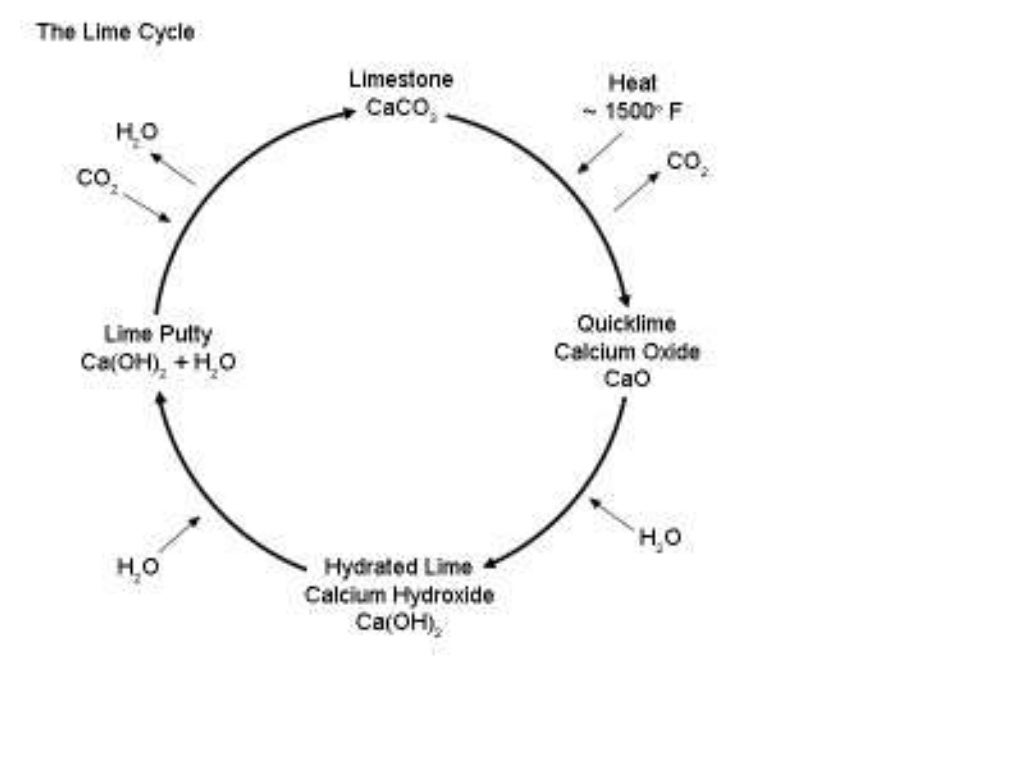

As the local neighborhood housing boss just asked me what it was for - I said yeah it's like cement only less intense. So it's less environmentally costly in terms of the temperature the lime got cooked at. The US hydrated lime though is cooked at a higher temp so it's not as reactive to water anymore. Or whatever.

Anyway let's look at the big haul of the day: My guess is this is about 600 pounds of concrete rubble:

But it's hard to say. I did take a tumble due to my boot lace unraveling as I stepped over their roof gutter. Luckily the haul, over 100 pounds, didn't land ON the roof gutter on the ground. Wow - that was a CLOSE one. haha.

So I can use this to fill the big ruts in the ground from driving onto the land - wetland.

AND I can use it as Cob aggregate.

Let's look at how I would use it as aggregate. I got a bag of quickcrete cement. I got the hydrated lime - that is like slow cement but it breathes (unlike cement) and it's more water proof than clay. I got a few bags of just Barn Lime (that does not react with the clay but it still does repel water. It just doesn't act as mortar)....I got the horse manure!

need a binder to hold them together and make them strong. For this reason a subsoil of no less than 15% clay is used as the crucial ingredient. Second, to further increase the durability of the bricks and to give them tensile strength, a fiber is added to the mix. This is usually straw or a sturdy grass, though other natural fibers can be used.

woven lattice of wooden strips called wattle is daubed with a sticky material usually made of some combination of wet soil, clay, sand, animal dung...

Sand provides the heat storage capacity of the mass, versus the clay which binds the material together.So with all those ingredients - I can do Slip Form building!

So it turns out that if you do a foundation of rock then you get less moisture since the clay breathes so much that it seeps in the frost too easily.

But the other thing to consider is that wet clay is a lot more electrically conductive - which is key for the Forest Cultivation of energy emptiness.

So it's just a gradient scenario.

A lot of these Cob concrete rubble images are for below ground foundations. But as I explained to the local boss - my land is like a geyser if you dig into it. No thanks. Don't get me wrong - I love the water. I'm just not gonna attempt a foundation again. I'm glad the land can't be "developed" (whatever that means).

So with the Kang Bed-stove itself you want MORE cement and MORE hydrated lime. So you have a 4 parts clay to 1 part cement and 1 part lime ratio. That is my understanding.

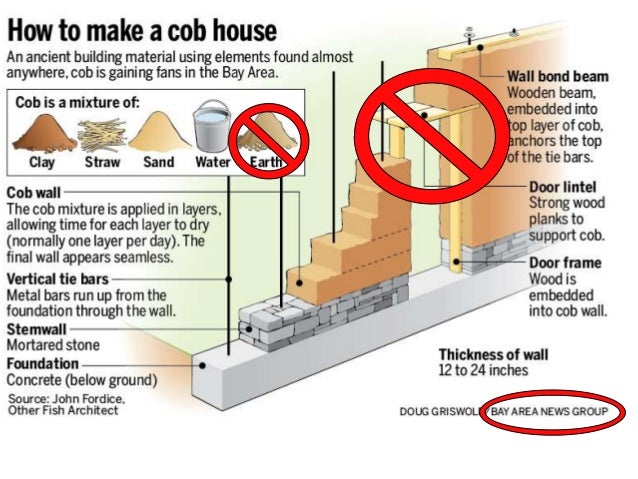

For the actual cob walls - you want about 10% lime at most and maybe just 2% cement - and then the horse manure straw and the clay - so the clay is about 80%. One recipe uses 1 part binder (lime-cement) to 2 parts clay to 3 parts straw. So normally you want a 3 parts sand to 2 parts clay but straw can take the place of sand a bit (apparently).

Aggregates give the mix its bulk and dimensional stability through materials such as mud, sand, crushed chalk and crushed stone. Reinforcement is provided by straw, hair, hay or other fibrous materials, and helps to hold the mix together as well as to control shrinkage and provide flexibility.[5]So the straw is for insulation while the clay is for heat absorption and radiation.

Closely spaced upright sticks or poles driven into the ground with small branches (wattle) interwoven between them make the structural frame of the wall.

The wattle may be made as loose panels, slotted between timber framing to make infill panels, or it may be made in place to form the whole of a fence or wall. The technique goes back to Neolithic times. It forms the substructure of wattle and daub, a composite building material used for making walls, in which wattle is daubed with a sticky material usually made of some combination of wet soil, clay, sand, animal dung and straw. Wattle and daub has been used for at least 6,000 years, and is still an important construction material in many parts of the world.

So obviously I'm not making a stone wall. But rather a cob wall with some rocks in it.

So this is much more what we are looking for - nice thick walls for insulation. The rock is for the foundation. Lots of straw. You can see I have the Scythe to haul up north - so I can harvest more straw when I run out of horse manure. The horse manure works amazingly well as it's the perfect length of straw.

I also am bring up a - what's it called - trimmer? clipper? A Lopper! Wow I learned a new word! I'm surprised.

A tree lopper that I'll use to cut the willows for the Wattle and Daub framing.

Pretty amazing!!

Maybe I will use those railroad ties - left up there. Kind of rotting but mainly not.

I would have to just lay them horizontal since again I absolutely do NOT want to dig post holes as they'll just fill up with water and create little lakes.

Many of them constructed of a small diameter timber frame atop a stone foundation. The earthen plaster was largely cracked and crumbling revealing a riven wattle and daub framework underneath. Their remaining small diameter polewood rooming members were in clear view, topped by fired clay ties. Most of these materials still retained their legacy as products harvested from traditional coppice management.Sounds perfect!

So build a mini version of this.

Let's look for "mini" versions of similar design.

So this is smaller - STILL not small enough. But it gets the point across.

This is a little bit smaller than what I'm thinking of - so that's the closest definitely.

The walls of a cob house are generally about 24 inches (61 cm) thickNot that tropical "cob-lite" stuff. haha.

still too big but has the stone foundation.

without a grate fuel could not be burnt completely. ...The improved stoves have grates with reduced combustion chamber and controlled air inlet and passage to kang. An area ratio of 1:1 for bars and gaps in grate is strongly recommended to ensure adequate primary air.Funny - I was just wondering why the Kang bed-stove had to use a grate above the fire - why not just a hole? Sure enough - if the grate opening is not big enough then the fire doesn't get enough oxygen from above.

The suspended kang is installed above the ground and so radiates from top and bottom surfaces.Exactly.

When normal burning starts, the smoke flow velocity reaches 3m/sec in the channel. The high temperature smoke flows into the kang, spreads out and its velocity drops quickly to about 0.1 m/sec after 1-1.5 metres in the bed. Due to turbulence the smoke fills the spaces and has time to transfer its heat.

Thus the construction materials must be good heat absorbers and conductors, have mechanical strength and long life and be available at affordable prices. Concrete is the first choice for the kang top followed by clay adobe.

According to research at Tongji University, “The Chinese Kang is an ancient integrated home system for cooking, sleeping, domestic heating and ventilation. It is still widely used today in nearly 85% of rural homes in northern China. In 2004, there were 67 million Kangs used by 175 million people.”https://www.permaculturevisions.com/tag/recycling/

So this article is arguing for the Rocket Stove over the Kang bed-stove?

I'm thinking maybe I should try using my Hunter stove - as I wanted to!! Yes a cleaner burner - and it's insulated. Paul Stamets thought it would not have enough "force" to heat the Kang bed - but I think it's worth a try.

Insulation in a firebox is vital for conserving energy. As a result, the outer area of the stove stays cool. Only the flue heats up. In well insulated stoves, the energy is concentrated on the cook-top. In China, locally made mud-straw bricks surround their stoves. Sand or ash in the mud-brick can ensure even higher insulation-rates. The Kang utilises the residual chimney heat. The chimney gases travel from the cooktop through the wall and fan out along a set of tunnels under the bed in the next room, then up a chimney on the next wall. Unlike the insulated stove, the bed has plenty of thermal mass, and the mattress is thin. So, the bed is toasty warm up by the time the dishes are washed.

So it's not an "either/or" argument.

OK FASCINATING!!

A white man tries to build a wattle/daub hut but goes against the circular wall design - and then his roof sags from too big of area.

That's my previous blogpost.

That's a master's thesis with the white man design roof sagging!! too funny. Oops.

The original human culture uses a CIRCULAR wall design for a reason and not just in honor of the female energy.

Traditional Chinese frame for adobe house

No comments:

Post a Comment