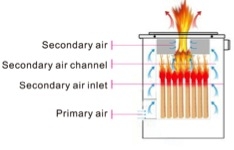

Here you can see the holes in the rim of the steel - where the biogas comes out of the secondary air chamber and then is burned off - once the pot or pan is put on top of the Hunter stove.

So there is that ring of holes and then another about 4 inches down - is another ring of holes.

That is where the secondary air comes in - once the front air is closed off - so then the air gets preheated.... I'm talking about those tiny vents. The big hole on the top is for the chimney pipe....

So the chimney is missing two top sections (for now) - so that means I don't get as much of a vacuum draw from the hot air sucking up, as it expands while rising.... But I still get a chimney effect, as I'll show.

This is the Swedish fire started - I think it's called "Light my fire" and that square metal has an "edge" to it just on one side. So you need to make sure that edge is facing the magnesium rod. Then that magnesium metal is somehow stronger than the usual magnesium. But you still are scraping off a spark that then lands on the cotton ball.

So the cotton ball petroleum jelly is burning nicely.

So at first you keep the bottom front vent open to have a lot of air flow to get the wood burning.

So you can see smoke coming out of the chimney because the front vent is still open.

Now with the vent closed there is now no smoking (hardly any) coming out of the chimney!! Presto - the fire is still going inside but the biogas vents are burning off the smoke.....

Pretty awesome.

Second grilled cheese sandwich cooking - and still NO smoke out of the chimney!! (hardly any) So the fire is indeed still going and yet no smoke!! Is that cool or what?

Hunter Specifications:

Cooking Fire Power: ≥ 1.5 KW

Thermal Efficiency: ≥ 35% (StoveTec/EcoZoom 30%)

Emissions Concentration (smoke): ≤ 25mg / m3

SO2 ≤ 20mg / m3

NOx: ≤ 120mg / m3

CO: ≤ 0.1%

Still no smoke as that 2nd grilled cheese sandwich finishes up.

OK so there you have it folks. A Biogas TLUD cooking stove in action.

Now the mistake I made was to try to take a photo of a "blue flame" out of the Hunter stove. What happened is the air inside got too cold - and some of the wood was probably damp.... and the thing just went out and was smoking. With the top open then the secondary vents blow the emissions back down into the fire so that the fire goes out.

You should see no smoke unless operating the stove incorrectly, or you have damp fuel. Airflow control is extremely easy with this stove. You top light it like a candle and it burns down. The ventilation door should be closed after the flame is established. You also do not have to tend this stove like a rocket stove during high fire power operation....I used eight 3/4 inch by 3/4 inch scraps of hardwood flooring each about 5 inches long for fuel. Once started, I didn't touch the stove except for an occasional peek at the progress until the fuel was exhausted...But that was due to operator error. Can we get a photo of a blue flame from the biogas vents on the Hunter stove? I know we can from the Survivor rocket stove (that also has biogas secondary vents).... Let's see.

Ah - my fuel size was wrong!! I had either too big or too small

the TLUD operates optimally using granular fuels that are between the size of cat food and walnuts. Smaller fuel constricts the draft and can't sustain a flame, and larger, looser fuel has too much air flow, and yields more ash.

This review on youtube might show blue flames

Not really. In fact he lights the stove the wrong way!! You're supposed to light it from the Top down - after it is fully loaded! Amazing how many of these "reviewers" (business promoters) do NOT even understand HOW a gasifier stove works!!

From the Silverfire website: Introducing the SilverFire® Hunter, a lightweight, portable natural draft chimney stove designed for both indoor & outdoor use! The Hunter is a top lit updraft gasifier (TLUD), powered by twigs, yard scrub, or any flammable biomass (why buy fuel?). TLUD's stoves utilize a batch fed combustion chamber. It is simple to operate. Vent the chimney outdoors to eliminate all household emissions. Insert vertical positioned fuel into the combustion chamber; next place a little tinder on top and light! To fine tune your flame adjust the ventilation door at the bottom of the stove. That's all there is to it! The portable SilverFire® Hunter model opens up a new frontier in biomass clean cook stoves. You now have the capacity to eliminate all household emissions! TLUD technology has been around for over 100 years. Primary air passes through your fuel as it combusts in the combustion chamber and becomes carbon monoxide gas. The carbon monoxide gas is then burned and mixed with the preheated secondary air, above the fire. The secondary air combustion appearance is like a gas stove and is know as a Chinese burner. The end result of your biomass fuel is to produce minimal amounts of ash, soot, and bio-char, which is required to be removed from the stove after cooking for maximum stove performance.

I used a 3 inch elbow and a 3 inch to 6 inch adapter to hook it up to a chimney I was using for a wood stove I no longer have installed. The only downside is cleaning the stove, the only way to clean out the ashes is to turn the stove upside down and dump the ashes out, to do this you have to disconnect the stove pipe, the stovepipe will have fine ash inside and you have to be careful not to make a mess you will have to clean up, best to have a bucket close by to set the end of the stovepipe in....Yeah I was thinking of getting a 6 inch adapter....

In the event you want to slow the cooking process down (e.g. slow cooking with cast iron) add thicker, dense fuel into the combustion chamber. Dense material takes longer to burn, ideal for slow cooking. Combustion in the Hunter produces very little smoke or soot, if using dry fuel. The beauty of the Hunter is that the first 20 - 40 minutes of cooking is high fire power (boiling operations, browning meat, etc...), then for the next two hours a wonderful diminishing, simmering heat is present (low fire power cooking). The stove is dialed in for maximum cooking performance. At any time, you can also just add more fuel and primary air to stoke the stove back up to high fire power cooking too! Just add fuel and open the ventilation door a couple of fingers to add primary air is all that is required.But one has to be very careful....

only burn the dryest, smallest split wood you can find, ALWAYS use fire starters, newspaper is not worth the hassle. Do not use this inside a structure, unless it is vented and fanned, or you LOVE the smell of wood smoke, and mayhaps the sound of cursing.Another youtube review

So that review wrongly emphasizes the need for space between the loaded wood - for air. See my quote below from Dr TLUD himself that emphasizes - the whole point of the biogas stove is that the air does not come into direct contact with the burning fuel - but only with the secondary gas from the burning fuel (separated by the biochar). We shall see the details on this.

So after studying the below TLUD business in India - they emphasize the need for primary air to remain - not too much wood in the bottom. (Oh wait - that was a DIFFERENT stove - not the gasifier Champion stove - just a rocket stove). This Hunter stove review - he keeps the primary fully open the whole time.

3rd review on youtube

This stove cooks with a cadence that is wonderful when understood: the first 1/2 hour or so utilizing high firepower, then the following period is lower fire power with heat still coming out of the combustion chamber a couple hours later if densely packing with twigs. There are 3 levels of combustion and it is significantly faster cooking and more efficient than a primary combustion rocket stove. The Hunter stove does not go out when used correctly. There are lots of videos on the SilverFire website demonstrating correct operating procedures. The number one advantage is you do not have to tend this stove after you light it, unlike a rocket stove. Longer duration burns are achieved with denser fuel.Biomass Biogasification stoves in India - wins sustainability award - youtube

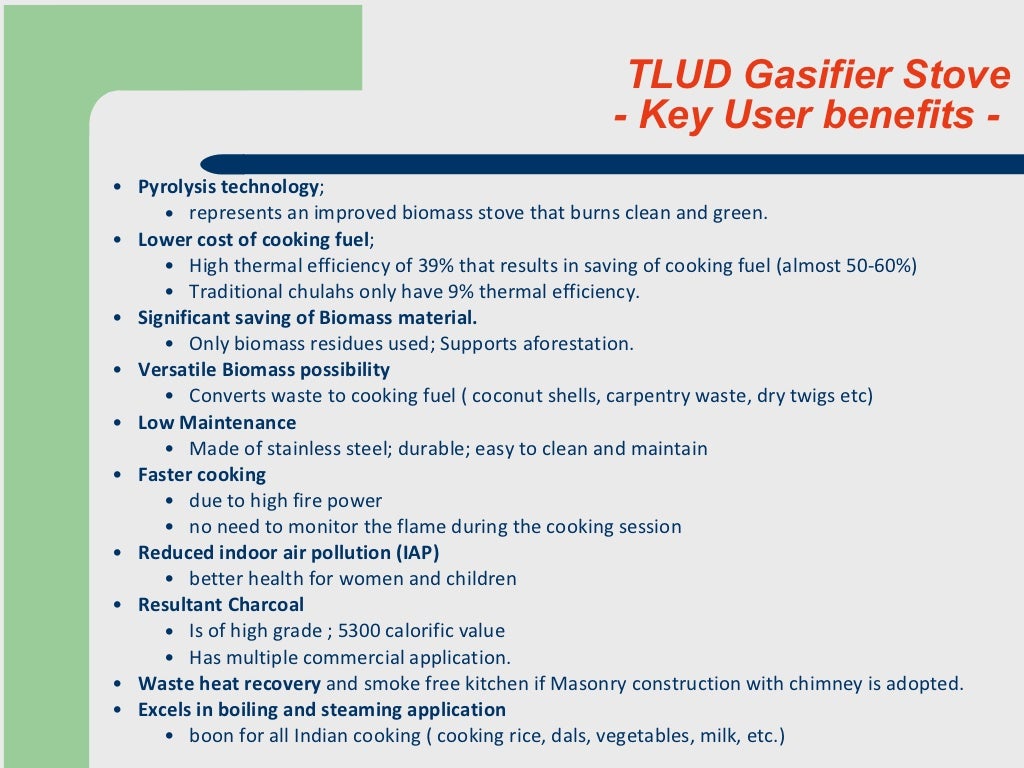

Servals TLUD biogas stove in India - youtube - similar design as Hunter stove!

TLUD in India - vid Anganvadi

http://servalsgroup.blogspot.com/Servals wins the Sankalp 2010 Award in Clean Energy

I am happy to announce that Servals are the proud winners of the Sankalp 2010 award in the Clean Energy Sector.

We won the Sankalp award for our energy solution around the TLUD Gasifier Stove.TLUD stove in India - details - vid on youtube

SERVALS champion biogas stove

So we can see this is almost precisely the same claims as the Hunter Silverfire TLUD stove!!

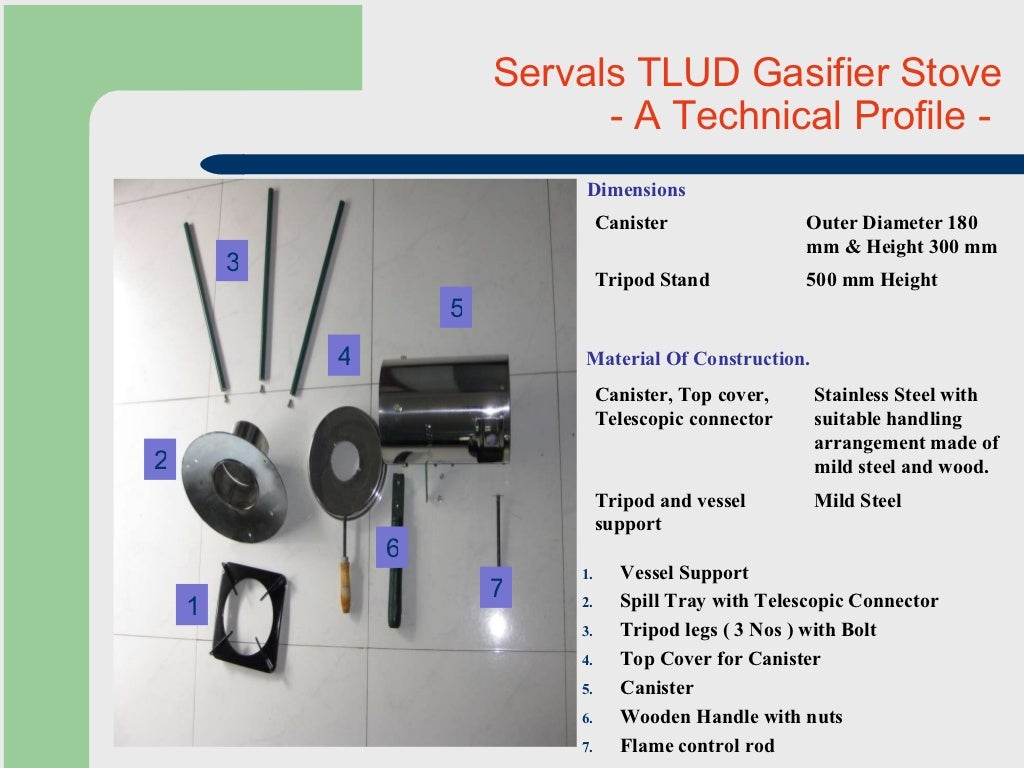

So this has this "spill tray with telescopic connector" as a Damper on the flame heat level.

The Hunter stove does not have that capability.

Instead you get three levels of heat based on what stage the fire is at - a primary burn at the top, a primary burn at the bottom or a charcoal burn.

TLUD means Top Lit Updraft. This is different from most of the ordinary cooking stoves which are Bottom Lit Updraft. There is a lot of interest in TLUD technology around the world since this saves around 65-75 per cent fuel material compared to a traditional 3-stone fire wood stove.So Dr. TLUD helped design that stove in India... here is his keynote talk in 2012... on TLUD stoves...

It also reduces the cooking time by half.

Gases from Biomass. Biogas is a well known term. It's rotting manure and everything like that. It's anaerobic digestion. It's giving you a very clean gas, that can be burned very very cleanly. And they took the name biogas. When you take some solids, some wood and you're gonna be pyrolyzing it - it is technically Biogas. So we use the term "wood gas" or Pyro gas or these types of things like that.So that means there is NO NEED to create "air" within the wood pile in the stove. Fascinating! Several of the youtube reviews do NOT understand how the Hunter stove works - and so think you need AIR space between the wood - when loading the stove.... BUT NOW WE KNOW THE TRUTH from Dr. TLUD himself!!!

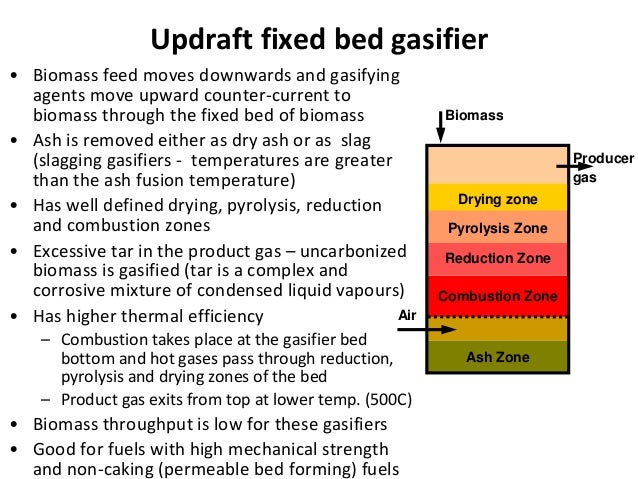

Now the KEY element here for its cleanliness is they are gases being burned. The reason that these Microgasifiers are cleaner burning stoves is that the oxygen that is coming in for doing the combustion ONLY has contact and mixes with GASES. It's not out there mixing with the wood or the other fuels and things like that. GASIFIERS separate the creation of the gases from where thoses gases are being combusted. That separation might be a matter of a few centimeters or a matter of a few milliseconds. However it is separated and it greatly facilitates the mixing and the turbulence and stuff so you can get a clean burning into there.

things which are locally available in rural areas. To get a fast ignition we are now creating these gases right in the very top in there. Those gases come up and they give you a flame with a punch... just as if it's the last of that burn or the middle part and the last of that particular burn.

We light it. We have high heat in the beginning.

This is not the raging fire at the top.....It does not make this chamber glow red hot. You get to the bottom and you let that Primary Air flow in with full force - You can make that metal glow red hot on the bottom and it will shorten the life of the stove. I've been saying for years TAKE THE CHAR out. Dump it out..........................................................................

For over a hundred years scientists and engineers have known that combustion of biomass is cleaner when the air is well mixed with only combustible gases, instead of having the combustion occur in zones where solid fuel is still present. The creation of combustible gases that are separate from the

combustion of those gases is a clearly distinguishing characteristic of a true "gasifier".

Practical gasification in small devices (i.e., micro-gasification) was not achieved until

1985 when Dr. Thomas B. Reed conceptualized and accomplished what is now called

"Top-Lit Updraft" (TLUD) gasification with batches of biomass fuel. In 2004 Dr. Paul S.Anderson created a variation of traditional updraft micro-gasification with continuous-operation, being called AVUD for "Another Variation Updraft" to distinguish it fromconventional updraft gasifiers. To achieve these advances, Drs. Reed and Andersonmainly do practical experimentation based on combustion theory and principles*.

webcache link

Gasification 101 - you only want 1/4th the amount of oxygen needed for a complete burnA 15 inch (38 cm) riser or "pre-pot internal chimney" is needed to achieve thenatural [UP] draft, but additional chimney height is needed at elevations above 3000 feet (1000 meters).

No comments:

Post a Comment